- Position:

- Batte Melt pump > NEWS >

BOPP film extrusion melt pump

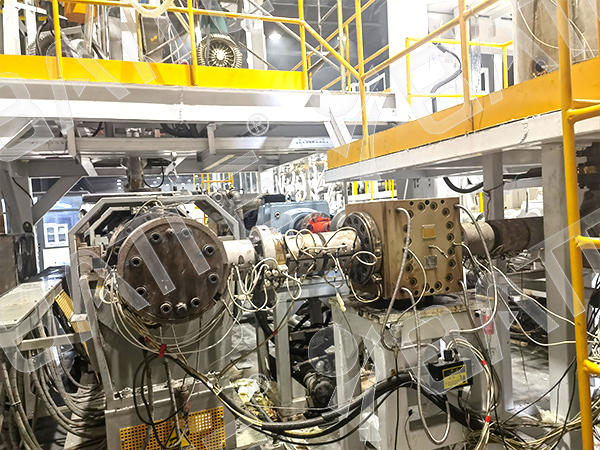

The melt pump serves as a core auxiliary device in BOPP (biaxially oriented polypropylene) film extrusion production lines, playing a pivotal role across critical functions including pressure control, quality enhancement, energy consumption optimization, and equipment protection. The following provides a detailed analysis:

I. Core Functionality: Pressure Stabilization and Efficiency Enhancement, Fortifying Quality Foundations

Precise Pressure Stabilization and Flow Control

BOPP film demands extremely high thickness uniformity (thickness deviation must be controlled within ±1%). During extruder operation, pressure fluctuations often arise due to changes in melt viscosity and screw speed variations, directly causing film thickness deviations. The melt pump utilizes a sealed chamber formed by precision gear meshing to control melt pressure fluctuations within ±1% (compared to ±5%-10% in traditional extruders), eliminating thickness inconsistencies caused by unstable melt supply at the source. For example, after implementing a melt pump, one company reduced film thickness deviation from 5% to below 1%, significantly improving yield rates in subsequent processing stages like slitting and printing.

Enhancing Film Uniformity and Optical Properties

The rotational motion of the melt pump's gears enables smooth melt conveyance, reducing melt pulsation and minimizing defects like bubbles, streaks, and thickness inconsistencies in the film. By adjusting the pump's speed or displacement, extrusion volume can be precisely controlled to achieve uniform film thickness distribution. This enhances flatness and optical properties (such as light transmittance and haze), meeting the demands of high-end packaging, capacitor films, and similar applications.

II. Process Optimization: Reducing Load for Flexible Production

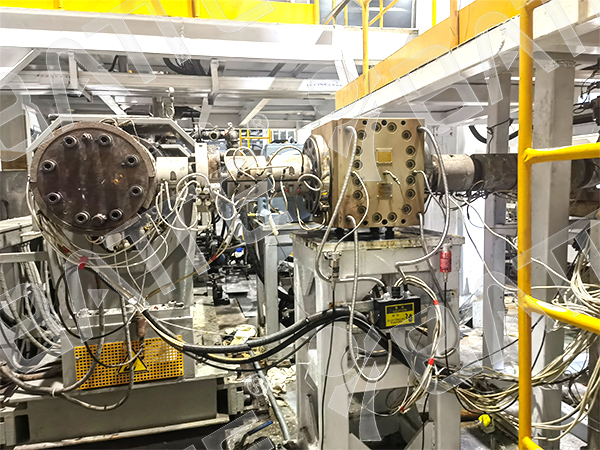

Sharing Extruder Pressure to Extend Equipment Lifespan

In traditional production, extruders bear the entire pressure of melt conveyance alone, resulting in high screw workload, elevated energy consumption, and unstable operating conditions. Melt pumps alleviate this pressure, enabling extruders to operate under smoother conditions. This extends screw lifespan by over 30%, reduces thrust bearing load on gearboxes by 20%, and extends maintenance intervals from monthly to quarterly.

Enhanced Process Adaptability

The integration of melt pumps improves the flexibility of extruder speed adjustment, facilitating easier adaptation to production requirements for BOPP films of varying widths and thicknesses. For instance, by adjusting the pump's displacement, production can be swiftly switched between films ranging from 0.018mm to 0.050mm in thickness. This eliminates the need for frequent extruder parameter adjustments, significantly reducing mold changeover time.

III. Energy Efficiency and Environmental Protection: Reducing Energy

Reduced Mechanical Energy Conversion to Heat

The melt pump enables the extruder to operate at lower pressure, reducing heat generated by screw shear and decreasing mechanical energy conversion to heat by 30%. For instance, after implementing a melt pump, one enterprise achieved approximately 25% lower energy consumption per kilogram of processed material, yielding annual electricity savings equivalent to reducing 42,000 tons of carbon dioxide emissions.

Optimized Temperature Control

The melt pump's precise displacement control reduces heating power by 20% while minimizing melt degradation risks caused by temperature fluctuations. For instance, during high-transparency BOPP film production, the melt pump maintains melt temperature within ±1°C, preventing defects like crystallization spots and black spots.

The melt pump serves as both the “quality guardian” and “efficiency engine” of BOPP film extrusion lines. Its multifaceted advantages—including voltage stabilization, efficiency enhancement, energy savings, and environmental benefits—not only significantly improve film quality and production efficiency but also reduce equipment maintenance costs and energy consumption. This empowers enterprises to transition toward high-end and green manufacturing. With advances in materials science and precision manufacturing technology, the application scope of melt pumps will continue to expand, becoming a critical pillar for high-quality development in the BOPP industry.

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755