- Position:

- Batte Melt pump > NEWS >

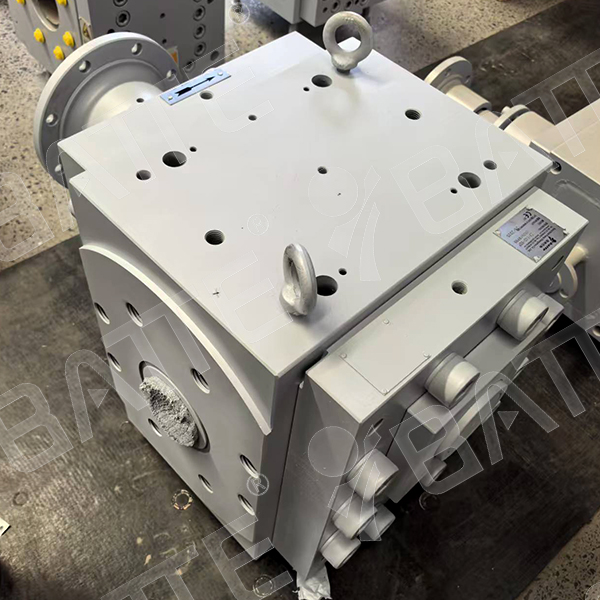

Plastic pipe extruder melt pump

Pipe extruder melt pump is a high temperature and high viscosity polymer melt conveying, pressurizing and metering equipment specially designed for pipe production line, its core functions, technical advantages and typical application scenarios are as follows:

I. Core function and working principle

Positive displacement conveying

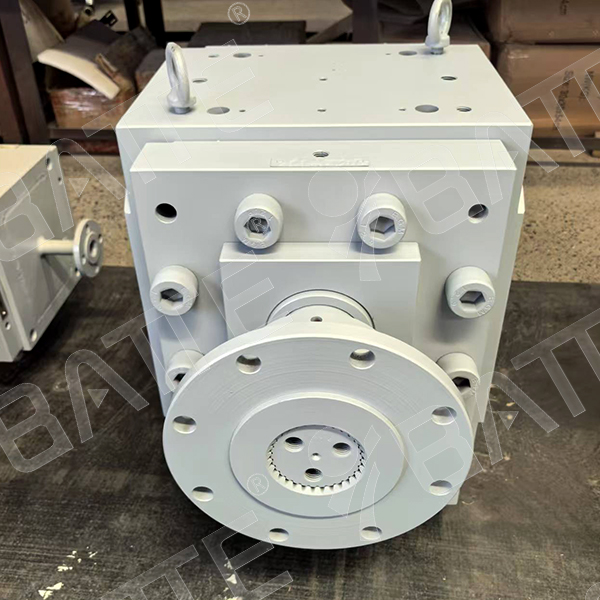

Through gear meshing to form a closed volume chamber, the melt is forced to be pressed and sent to the outlet, and the flow rate is strictly proportional to the pump speed to ensure conveying stability. For example, the Bart ZB-C series adopts a high-precision gear clearance design, which eliminates fluctuations in extrusion pressure and realizes precise control of pipe size.

Pressurization and Pressure Stabilization

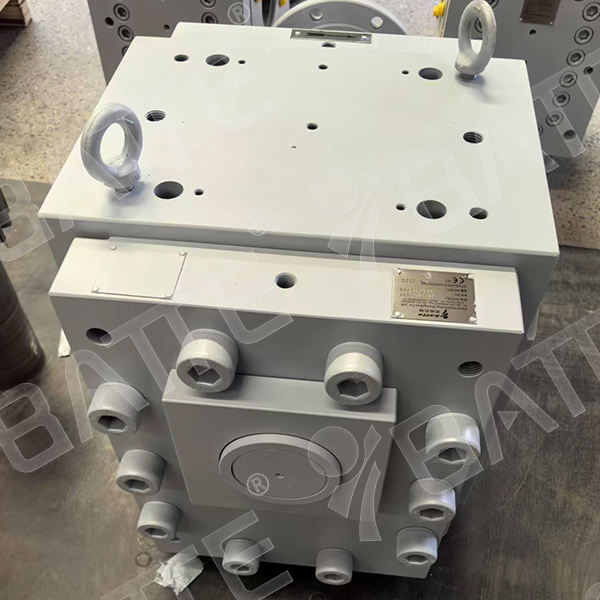

transfers the extruder's depressurization function to the melt pump, allowing the extruder to operate at low pressure and low temperature while establishing a stable head pressure. Zhengzhou Batte ZB-B series outlet pressure can reach 40MPa, adapting to the needs of conveying high viscosity materials (such as PE, PP, PVC).

Metering and Feedback Control

Integrated Siemens PLC control system monitors pressure, temperature, flow rate and rotational speed in real time and supports automatic/manual mode switching. For example, Bart ZB-B series shorten the material residence time and optimize the plasticizing effect through linear runner design, which is suitable for the production of transparent pipes such as PC and PMMA.

II. Technical Advantages

Improve product precision and stability

Eliminate charging error and screw pulsation, minimize the dimensional tolerance of extruded products, and reduce the scrap rate significantly.

Typical example: in PVC pipe production, the use of melt pumps to improve wall thickness uniformity by 30%, reducing raw material costs by 15%.

Energy saving and equipment protection

The extruder operates at low pressure and low temperature, energy consumption is reduced by 20-25%, screw axial force is reduced, and equipment life is extended.

For example, ZB-B series adopts nitrided tool steel gears (hardness RC45-50), which improves wear resistance by 50% and extends the maintenance cycle to 8,000 hours.

Multi-scenario adaptability

Supports co-mingling modification and direct extrusion of products (no pelletizing process) to simplify the process.

It can be connected in series with single/twin-screw extruder to realize stable production of large pipes (e.g. caliber ≥1200mm).

Typical Application Scenarios

Pipe production line

Processing materials: PE, PP, PVC, PPR, PB and other thermoplastics.

Core function: solving the problem of extruder exhausting and bubbling material, improving the pipe ring stiffness and bursting pressure. For example, Haike MP-M series makes melt pressure fluctuation ≤±1.5% in the production of HDPE gas pipe, which meets GB/T 15558 standard.

Co-extruded Composite Pipe

Precise control of multi-layer structures (e.g. aluminum-plastic composite pipe) is achieved by synchronous feeding of multiple melt pumps.

Typical configuration: 3 sets of ZB-B series pumps convey inner PE, rubber and aluminum layers respectively, with the thickness deviation between layers ≤ 0.05mm.

Special pipe production

High temperature resistant pipe (such as PPS, PEEK): working temperature ≤ 400 ℃, cleaning temperature ≤ 450 ℃.

Transparent pipe (such as PC, PMMA): low shear design to avoid melt rupture, light transmission rate ≥ 92%.

Email: sale@meltpump.com

WhatsApp: +86 158 3833 1071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755