- Position:

- Batte Melt pump > NEWS >

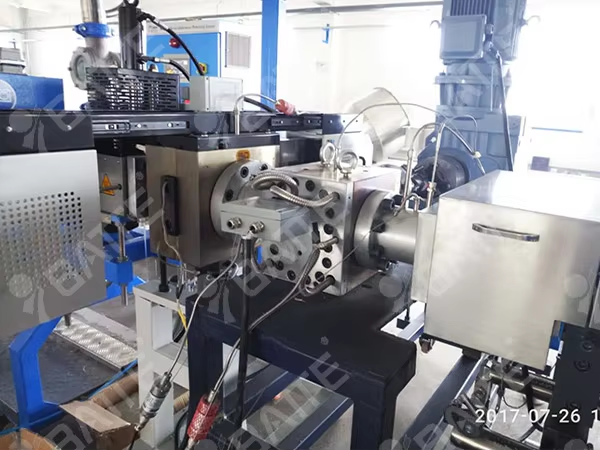

Enhance Efficiency and Precision in PU Underwater Pellet Extrusion with Advanced Melt Metering Pumps

In the demanding world of polyurethane (PU) underwater pellet extrusion, achieving consistent product quality, high throughput, and minimal downtime is non-negotiable. Central to this process is the melt metering pump—a critical component that ensures precise polymer flow control, uniform pellet formation, and optimal energy efficiency. For manufacturers seeking to elevate their production lines, here’s why investing in cutting-edge melt metering pumps is a game-changer.

Why Melt Metering Pumps Are Indispensable in PU Underwater Pelletizing

Consistent Material Delivery:

PU materials are sensitive to temperature and pressure fluctuations. Melt metering pumps provide volumetric accuracy, eliminating flow irregularities that cause pellet size variations. This consistency directly impacts end-product quality, reducing waste and customer complaints.

Enhanced Process Control:

Advanced pumps integrate smart control systems (e.g., PLC-driven or IoT-enabled interfaces) to adjust output in real time. This adaptability ensures seamless operation even with abrasive additives or varying batch viscosities, maintaining line stability during high-speed extrusion.

Energy and Cost Savings:

By optimizing melt pressure and reducing rework, these pumps lower energy consumption and material waste. Long-term, this translates to significant cost savings and a smaller carbon footprint.

Durability in Harsh Conditions:

Underwater pelletizing exposes equipment to moisture, high temperatures, and corrosive chemicals. Premium pumps feature hardened steel gears or tungsten carbide coatings to withstand wear, extending maintenance intervals and lifespan.

Key Features to Look for in a Melt Metering Pump

Precision-Engineered Design:

Gear or screw pumps with tight tolerances ensure minimal pulsation, critical for uniform pellet cutting in underwater systems.

Modular Construction:

Easy disassembly for cleaning and maintenance without line shutdowns.

Variable Speed Control:

Adjustable RPMs match production demands, from pilot runs to full-scale output.

Compatibility with PU Grades:

Pumps should handle diverse PU formulations, including those with fiber or flame-retardant additives.

Real-World Applications and Benefits

High-Output Lines:

For manufacturers scaling production, pumps with twin-screw designs deliver up to 50% higher throughput than single-screw models.

Flexible Material Processing:

Pumps equipped with heating/cooling jackets manage temperature-sensitive PUs, preventing degradation during extrusion.

Integration with Automation:

Seamless compatibility with SCADA systems enables predictive maintenance, reducing unexpected downtime.

Case Study: Success in Action

A leading PU foam manufacturer upgraded to a high-torque, dual-zone melt pump and reported:

18% reduction in pellet size deviation.

22% decrease in energy use due to optimized pressure control.

50% fewer maintenance stops after switching to wear-resistant materials.

Choosing the Right Partner

When selecting a pump supplier, prioritize vendors offering:

Application-specific expertise: Tailored solutions for underwater pelletizing.

Global service networks: 24/7 support and rapid spare parts delivery.

Innovation pipelines: Access to latest technologies like AI-driven diagnostics.

In PU underwater pellet extrusion, precision is not just a goal—it’s a necessity. Melt metering pumps are the linchpin of efficient, high-quality production, delivering measurable ROI through consistency, durability, and smart control. For manufacturers ready to future-proof their lines, investing in advanced pump technology is not just an upgrade—it’s a strategic imperative.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755