- Position:

- Batte Melt pump > NEWS >

Melt Pump for Extrusion: A Game-Changer in Polymer Processing

The polymer processing industry is witnessing a transformative shift with the widespread adoption of melt pumps for extrusion, a technology that is redefining efficiency, precision, and sustainability in manufacturing. These pumps, designed to precisely control the flow of molten polymer during extrusion, are becoming indispensable tools for producers of plastic films, sheets, pipes, and other extruded products.

What is a Melt Pump for Extrusion?

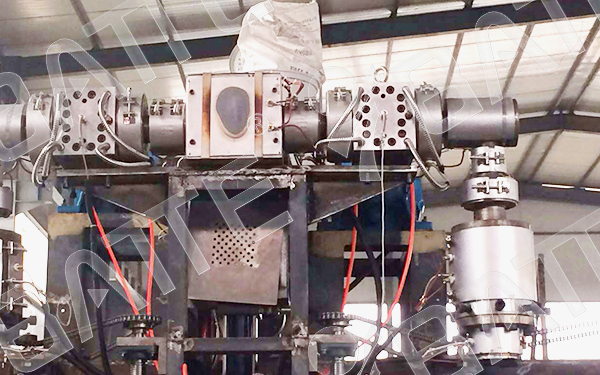

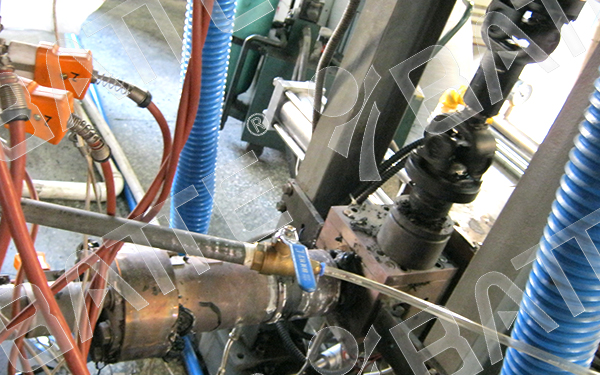

A melt pump, also known as a gear pump, is a high-precision device installed between the extruder and the die in an extrusion line. Its primary function is to regulate the pressure and flow rate of molten polymer, ensuring a consistent and uniform output. By stabilizing the extrusion process, melt pumps reduce variations in product thickness, improve surface finish, and minimize material waste.

Traditionally, extrusion processes relied solely on screw extruders to push molten polymer through a die. However, screw extruders often struggle with pressure fluctuations and inconsistent flow, leading to defects and inefficiencies. Melt pumps address these challenges by providing a steady, controlled flow of material, making them a critical component in modern extrusion systems.

Key Advantages of Melt Pumps

Improved Product Quality: By maintaining consistent pressure and flow, melt pumps ensure uniform thickness and superior surface quality in extruded products.

Enhanced Efficiency: Melt pumps reduce energy consumption by optimizing the extrusion process, leading to lower operational costs.

Material Savings: The precise control offered by melt pumps minimizes material waste, making them an eco-friendly choice for manufacturers.

Versatility: Melt pumps are compatible with a wide range of polymers, including polyethylene, polypropylene, PVC, and engineering plastics, making them suitable for diverse applications.

Industry Impact

The adoption of melt pumps is gaining momentum across industries, particularly in packaging, automotive, and construction, where high-quality extruded products are in demand. According to industry reports, manufacturers using melt pumps have seen a significant reduction in production downtime and scrap rates, translating to higher profitability and sustainability.

"Integrating a melt pump into our extrusion line has been a game-changer," said John Miller, Production Manager at a leading packaging manufacturer. "We've achieved a 20% reduction in material waste and a 15% improvement in production speed, all while maintaining exceptional product quality."

Technological Innovations

Recent advancements in melt pump technology have further enhanced their performance and reliability. Modern melt pumps now feature:

Advanced Sensors: Real-time monitoring of pressure, temperature, and flow rates for optimal control.

Adaptive Control Systems: Automated adjustments to maintain consistency even under varying production conditions.

Durable Materials: High-grade alloys and coatings that extend the pump's lifespan and reduce maintenance requirements.

As the global demand for high-quality extruded products continues to rise, the role of melt pumps in extrusion is expected to grow. Researchers are also exploring the integration of melt pumps with Industry 4.0 technologies, such as IoT-enabled monitoring and AI-driven process optimization, to further enhance their capabilities.

"The future of extrusion lies in smart, efficient technologies like melt pumps," said Dr. Sarah Thompson, a polymer processing expert. "As we move toward more sustainable manufacturing practices, melt pumps will play a crucial role in reducing waste and energy consumption."

Melt pumps for extrusion are proving to be a vital innovation in the polymer processing industry, offering unmatched precision, efficiency, and sustainability. As manufacturers increasingly prioritize quality and environmental responsibility, melt pumps are set to become a standard feature in extrusion lines worldwide. This technology not only boosts productivity but also aligns with global efforts to create a more sustainable future for manufacturing.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755