- Position:

- Batte Melt pump > NEWS >

What are the applications of melt pumps in the rubber industry?

The applications of melt pumps in the rubber industry are extensive, mainly reflected in the following aspects:

I. Transportation and Pressurization of Rubber Melts

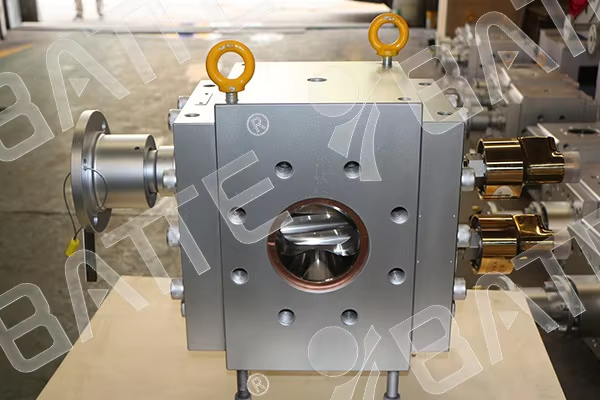

Melt pumps are primarily used for the transportation and pressurization of rubber melts. During the rubber production process, melt pumps can pressurize and stabilize the high-temperature rubber melts from the extruder before stably delivering them to the extruder die. This process ensures stable pressure and precise flow rate of the rubber melts during transportation, avoiding common issues such as pressure fluctuations and uneven flow rates in traditional extrusion systems.

II. Extrusion Molding of Rubber Products

Melt pumps play a crucial role in the extrusion molding process of rubber products. They can be used for the extrusion of various rubber products, such as tires, rubber tubes, and seals. Through the precise transportation and pressurization of melt pumps, the dimensional accuracy and surface quality of rubber products can be ensured, improving the product qualification rate.

III. Improved Production Efficiency and Energy Saving

The application of melt pumps also significantly enhances production efficiency and achieves energy saving in rubber production. Since melt pumps can stably transport rubber melts, fluctuations and waste during the extrusion process can be reduced, leading to improved production efficiency. Additionally, melt pumps can reduce the backpressure of the extruder, decreasing the axial force borne by the screw and thus extending the service life of the equipment. Furthermore, the tandem use of melt pumps and extruders enables low-temperature extrusion, further reducing energy consumption.

IV. Optimization of Rubber Production Processes

Melt pumps also have an optimizing effect in rubber production processes. They can precisely measure and transport rubber melts, ensuring material balance and stability during production. At the same time, melt pumps can coordinate with other production equipment to achieve automated production, enhancing the overall efficiency of the production line.

V. Adaptability to High-Temperature, High-Viscosity Conditions

Rubber melts typically have high-temperature and high-viscosity characteristics, and melt pumps are designed to adapt to such conditions. They can operate stably in high-temperature and high-viscosity environments, ensuring smooth transportation and pressurization of rubber melts. This characteristic gives melt pumps unique advantages and application value in the rubber industry.

In summary, melt pumps have extensive applications in the rubber industry, not only improving production efficiency, achieving energy saving, optimizing production processes, but also ensuring the quality and dimensional accuracy of rubber products. With continuous technological advancements and expanding markets, the application prospects of melt pumps in the rubber industry will become even broader.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755