- Position:

- Batte Melt pump > NEWS >

What other materials can the PET filament extrusion melt pump be used for?

The PET filament extrusion melt pump is primarily used for melt conveyance in the production process of PET plastics. Its functions are mainly reflected in conveying PET raw materials, controlling the production process, improving product quality, and reducing production costs. Besides PET materials, this pump can also be used for the following types of materials:

Polymer materials: The PET filament extrusion melt pump can be used to convey various polymer materials such as PA (polyamide), PB (polybutene), PC (polycarbonate), PE (polyethylene), PS (polystyrene), HIPS (high-impact polystyrene), ABS (acrylonitrile butadiene styrene copolymer), PP (polypropylene), and PVA (polyvinyl alcohol).

Other high-viscosity materials: This pump can also be used to convey high-viscosity materials without particulate impurities, such as rubber, asphalt, paint, adhesives, dyes, coatings, lubricants, and polyols.

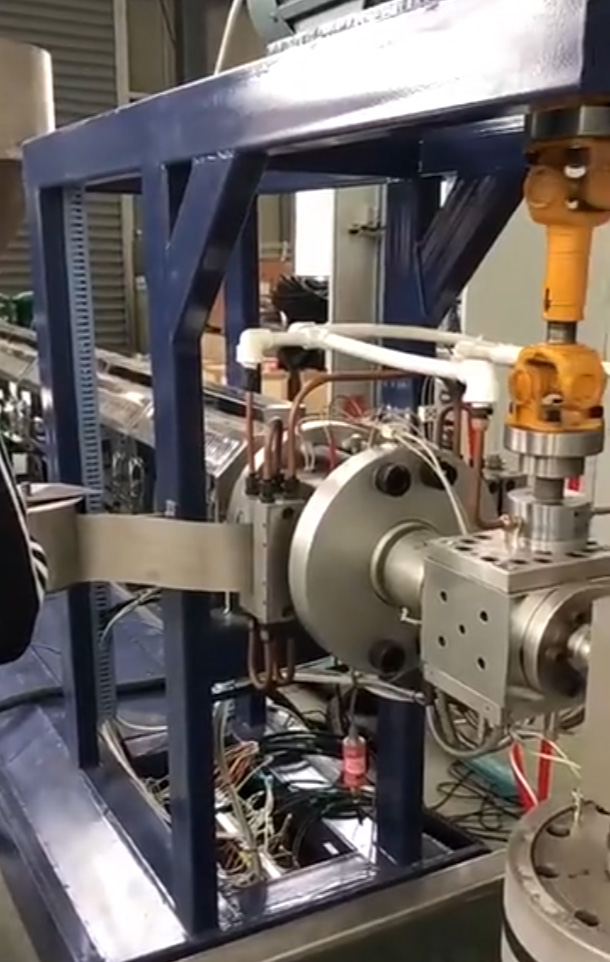

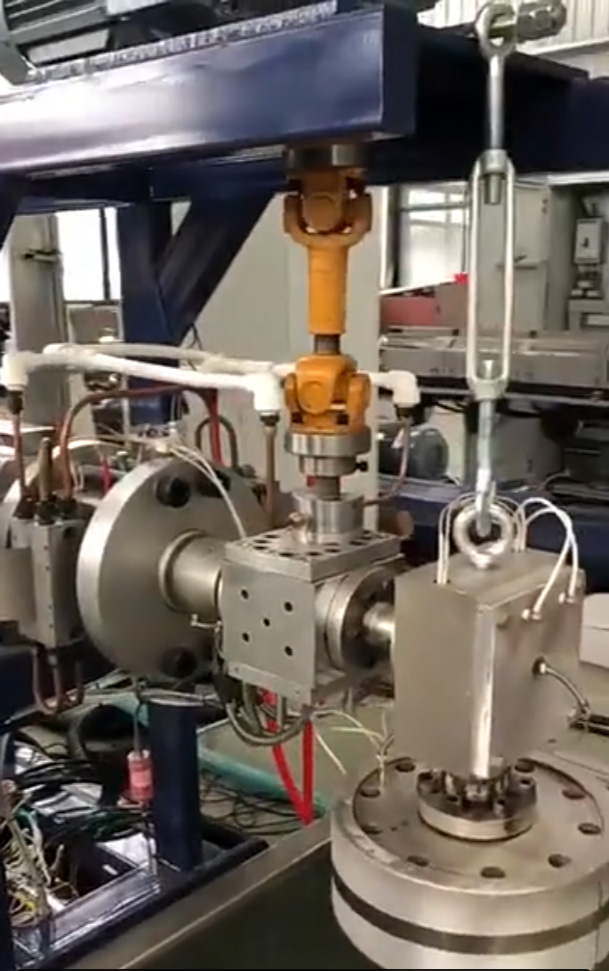

In the extrusion system, the PET filament extrusion melt pump is usually installed between the extruder outlet and the die head, or it can be installed in the pipeline for conveying high-viscosity pure materials. By adjusting the rotational speed of the melt pump, the pressure can be adjusted for pressure boosting or pressure stabilization, thereby significantly improving the stability of the die head pressure and effectively improving product quality. At the same time, this pump can achieve nearly linear output of flow rate, making flow control easier. Additionally, adding a melt pump can reduce the pressure requirements on the screw and reduce the load on the extruder, thereby saving energy.

In summary, the PET filament extrusion melt pump has a wide range of applications and is suitable for conveying and pressurizing various materials. When selecting this pump for use, it is necessary to select the appropriate model based on the specific material characteristics and production requirements to ensure the pump's normal operation and optimal performance.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755