- Position:

- Batte Melt pump > NEWS >

What are the specific application cases of melt pumps in the chemical fiber industry?

The specific application cases of melt pumps in the chemical fiber industry are extensive and diverse. Below are some typical examples:

Polyester Fiber Production

In the production process of polyester fibers, melt pumps play a crucial role. After polyester raw materials are melted at high temperatures, they are stably and continuously conveyed to the spinning die through melt pumps. Melt pumps can precisely control the flow rate and pressure of the melt, ensuring the stability and continuity of the spinning process, thereby producing high-quality polyester fibers.

Nylon Fiber Production

The production of nylon fibers also relies on the support of melt pumps. In the molten state, nylon raw materials are accurately conveyed to the extruder or spinning die through melt pumps. The stability and accuracy of melt pumps ensure the uniformity and strength of nylon fibers, improving product quality and market competitiveness.

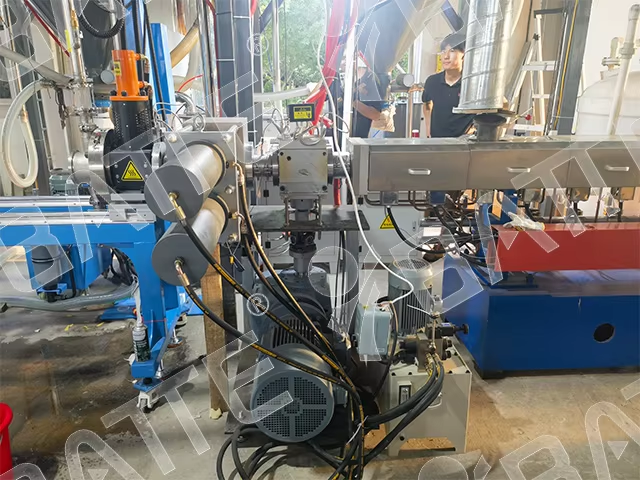

Melt Pressure Boosting and Conveying Systems

In the chemical fiber industry, melt pumps are often used to construct melt pressure boosting and conveying systems. These systems typically include components such as melt pumps, filters, heat exchangers, and control systems, capable of precise control, filtration, heating, and conveying of melts. For example, at a certain stage of the chemical fiber production line, melt pumps may be used to convey molten chemical fiber raw materials from the extruder to downstream spinning or drawing equipment, while maintaining stable melt pressure and temperature.

Reactor Discharge Pumps

In some production processes in the chemical fiber industry, melt pumps are also used as reactor discharge pumps. These pumps typically have large displacement and high pressure-bearing capacity, efficiently conveying molten materials from the reactor to subsequent processing equipment. For example, in the production process of polyester or nylon, melt pumps may be used to convey molten polyester or nylon from the reactor to the spinning die for spinning.

Customized Solutions

Due to the diversity and complexity of the chemical fiber industry, the application of melt pumps often requires customized design based on specific production needs and process conditions. For example, for certain specific chemical fiber raw materials or production processes, melt pumps with special sealing structures, wear-resistant materials, or heating methods may be required to meet production demands. Professional melt pump manufacturers are usually able to provide customized solutions based on customer requirements to ensure the best application effect of melt pumps in the chemical fiber industry.

In summary, the application cases of melt pumps in the chemical fiber industry are extensive and diverse, covering the production processes of various chemical fiber products such as polyester fibers and nylon fibers. By precisely controlling the flow rate and pressure of melts, melt pumps provide stable and reliable support for production in the chemical fiber industry, driving the continuous development and innovation of the industry.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755