- Position:

- Batte Melt pump > NEWS >

What is the application scope of plastic film extrusion melt pump?

The application scope of plastic film extrusion melt pumps is quite extensive. They are primarily used for the conveying, pressurizing, and metering of high-temperature, high-viscosity polymer melts, especially playing a crucial role in the production process of plastic films. Here are specific explanations of their application scopes:

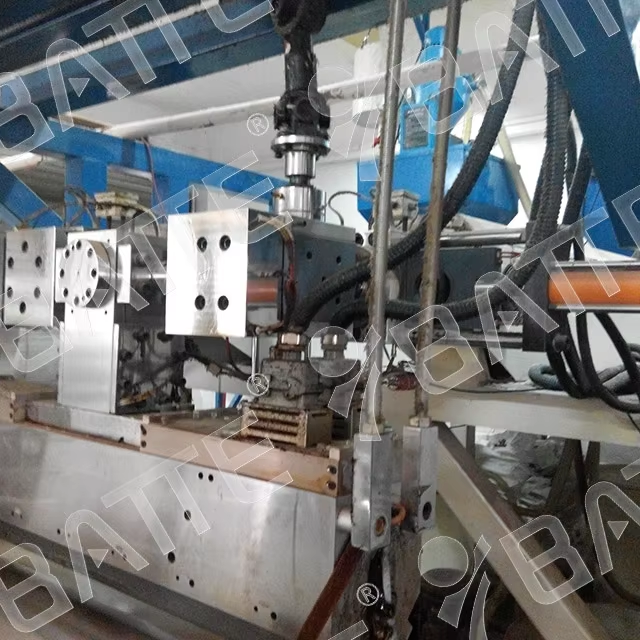

Plastic Film Production:

Melt pumps effectively pressurize and stabilize the high-temperature plastic melt from the extruder, then deliver it to the extruder die at a stable flow rate, ensuring uniform thickness and consistent quality of the plastic film.

Production of Other Plastic Products:

Apart from plastic films, melt pumps are also widely used in production lines for plastic products such as granules, pipes, sheets, and plates. They improve the dimensional accuracy and product quality of these items, reducing waste rates.

Processing of Polymeric Materials:

The materials that can be processed by melt pumps cover almost all polymeric materials, including PE, PC, PP, PVC, HIPS, PS, PA, TPU, and more. This gives melt pumps broad application prospects in the plastic processing industry.

Optimization of Extrusion Lines:

Connecting melt pumps in series with single-screw or co-rotating twin-screw extruders can significantly enhance the overall efficiency of the production line. They reduce the pressure requirements of the screws, enabling high-speed and efficient extrusion, and adjust the backpressure of the extruder to stabilize the plasticization process and lower the melting temperature, thereby increasing the output and quality of the products.

Energy Saving and Consumption Reduction:

The use of melt pumps can also substantially lower unit energy consumption. Compared to using extruders alone, combining melt pumps with extruders significantly improves mixing quality and output while reducing energy consumption.

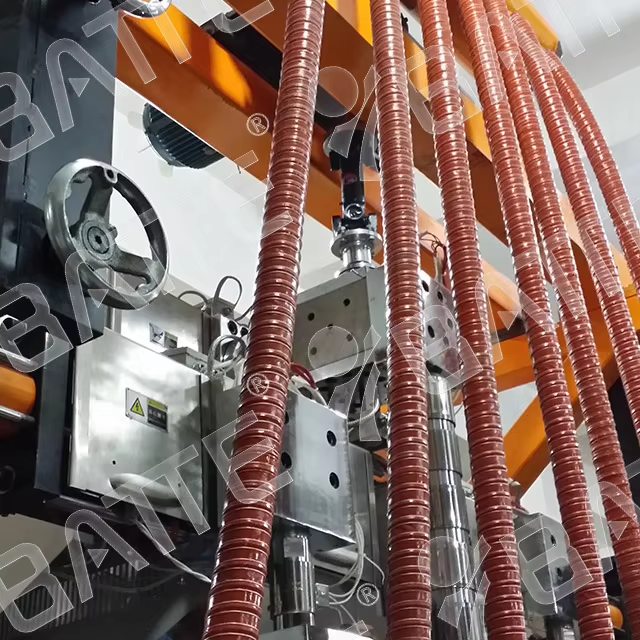

Multiple Configuration Applications:

Melt pumps can be used in conjunction with various equipment configurations, such as multiple small-to-medium-sized extruders simultaneously feeding into a single melt pump. The molten material is pressurized and metered by the melt pump before being supplied to the die for extruding large products (like large-diameter pipes, wide sheets, films, etc.). This configuration makes the production line compact, with a small footprint, while ensuring more precise cross-sectional dimensions of the extruded products and easier control.

In summary, plastic film extrusion melt pumps have a wide range of applications and significant value in the plastic processing industry. They improve product quality and production efficiency, reduce energy consumption and waste rates, bringing notable economic and social benefits to plastic processing enterprises.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755