- Position:

- Batte Melt pump > NEWS >

Advantages and characteristics of fluoroplastic extrusion melt pump

Fluoroplastic melt pump is corrosion-resistant, high-temperature resistant, with high conveying accuracy, low shear action, compact structure, high reliability, and easy maintenance and cleaning. It is suitable for high-precision conveying requirements in fluoroplastic processing. Fluoroplastic melt pumps have the following characteristics:

1、 Strong corrosion resistance

Material advantage: The pump body and gears are made of corrosion-resistant materials, which have good resistance to acids, alkalis, organic solvents, and other highly corrosive media. Therefore, various corrosive fluoroplastic melts can be transported. During long-term contact with corrosive media, the pump body and internal components are not easily corroded, maintaining good structural integrity and performance stability, greatly extending the service life of the pump.

2、 Good high temperature resistance

Adaptation to high temperature environment: During the transportation of fluoroplastic melt, it is often necessary to operate at higher temperatures, such as the processing temperature of polytetrafluoroethylene (PTFE), which is usually above 300 ℃. The fluoroplastic melt pump can operate stably in high temperature environments, withstand high melt temperatures, ensure smooth transportation and measurement of the melt, and meet the high-temperature process requirements of fluoroplastic processing.

3、 High conveying accuracy

Stable flow output: The gear structure of the melt pump acts as a rotating barrier, effectively blocking the impact of pressure and flow fluctuations in the feed area on the discharge area. When the inlet pressure of the pump fluctuates due to various factors, the outlet pressure and flow fluctuation of the pump can be controlled within a very small range of variation, which can achieve stable flow delivery and ensure accurate and uniform output of fluoroplastic melt.

Accurate measurement function: By precisely controlling the pump speed, precise measurement of fluoroplastic melt can be achieved, meeting the high-precision requirements for melt conveying during fluoroplastic processing, thereby improving the quality and dimensional accuracy of products and reducing waste rates.

5、 Compact structure and high reliability

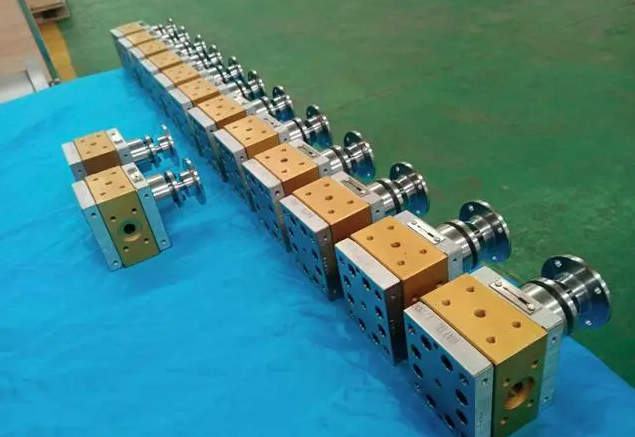

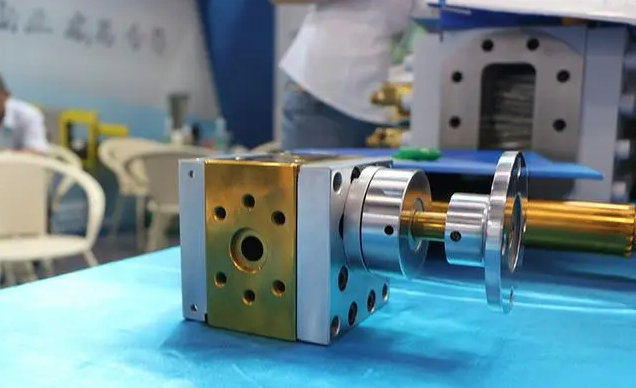

Reasonable structural design: Melt pumps are usually composed of pump body, driving gear, driven gear, sliding bearings, front and rear end plates, packing seals and other components, with a relatively simple and compact structure. The design of the fluoroplastic melt pump fully considers the characteristics and processing requirements of fluoroplastic melt, and the precision of the coordination between various components is high, which can ensure the stable operation of the pump.

Reliable work: With optimized structural design and high-precision manufacturing processes, the melt pump for fluoroplastics has good mechanical strength and wear resistance. It can maintain stable performance, low failure rate, and reliable operation during long-term operation.

6、 Easy to maintain and clean

Easy maintenance: The structure of the fluoroplastic melt pump is relatively simple, and the components are easy to disassemble and install, making it convenient for daily maintenance and upkeep. For example, regularly checking the wear of pump bearings, seals, and other components, and replacing worn parts in a timely manner, can ensure the normal operation of the pump.

Simple cleaning: Due to the high viscosity of fluoroplastic melt, it is easy to leave residues in the pump during use. The internal flow channel design of the melt pump for fluoroplastics is reasonable, with no dead corners, making it easy to clean the pump and effectively remove residual melt, avoiding any impact on the next transportation and processing.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755