- Position:

- Batte Melt pump > NEWS >

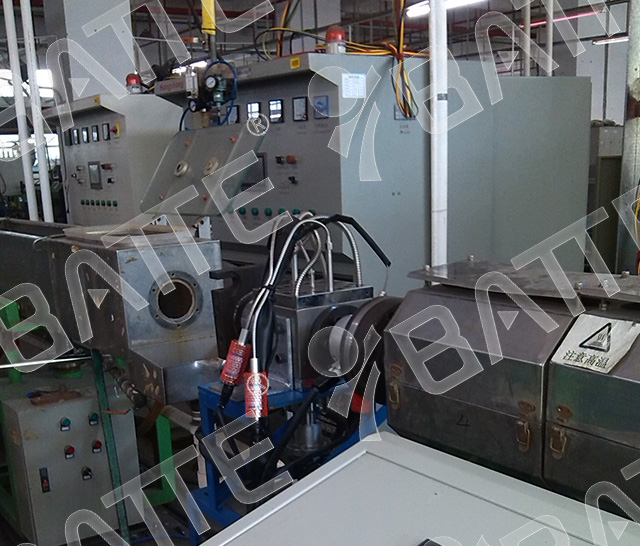

How to choose a melt pump for wire and cable production line?

When selecting a melt pump for a wire and cable production line, several key factors need to be considered to ensure it meets production requirements and operates at its best performance:

Production Capacity Demand

Firstly, it is essential to clarify the production capacity demand of the line, which determines the melt flow rate that the melt pump needs to handle. Based on the production volume, an appropriate melt pump model can be selected to ensure that it meets the production needs. Therefore, when choosing a melt pump, it is necessary to understand its flow rate range to ensure that the selected pump model can meet the actual flow rate demand of the production line.

Material Characteristics

The characteristics of the materials used in wire and cable production are also important considerations for selection. These include the viscosity, corrosiveness, toxicity, and whether the materials contain impurities such as particles. Different material characteristics have different requirements for melt pumps, so the appropriate pump model should be selected based on the material characteristics. For example, for high-viscosity materials, a melt pump with stronger conveying capability is required.

Working Pressure and Temperature

The working pressure and temperature of the melt pump are also factors that must be considered during selection. A pump that can withstand appropriate pressure and temperature should be chosen based on actual work needs to ensure stable operation and long-term use. Melt pumps in wire and cable production lines usually need to operate in high-temperature and high-pressure environments, so pump models with high temperature and high-pressure resistance are required.

Pump Type and Specification

The type and specification of the melt pump are also factors to consider during selection. Common types of melt pumps include extruder melt pumps, reactor melt pumps, and pipeline booster melt pumps. Each pump type has its characteristics and applicable scope, and the appropriate pump type should be selected based on the actual needs of the production line. At the same time, attention should also be paid to the specification parameters of the pump, such as gear speed and displacement, to ensure that the selected pump model can meet the actual needs of the production line.

Manufacturer and Brand

Lastly, the manufacturer and brand of the melt pump also need to be considered. High-quality manufacturers usually have advanced technology and rich production experience, able to provide melt pumps with stable performance and reliable quality. At the same time, melt pumps from well-known brands also have more comprehensive after-sales service and maintenance support, providing users with a better user experience.

In summary, selecting a melt pump for a wire and cable production line requires comprehensive consideration of factors such as production capacity demand, material characteristics, working pressure and temperature, equipment investment and maintenance costs, pump type and specification, as well as manufacturer and brand. By comprehensively evaluating these factors, the most suitable melt pump for the production line can be selected, improving production efficiency and product quality.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755