- Position:

- Batte Melt pump > NEWS >

Application of Melt Pump in Plastic Granulation

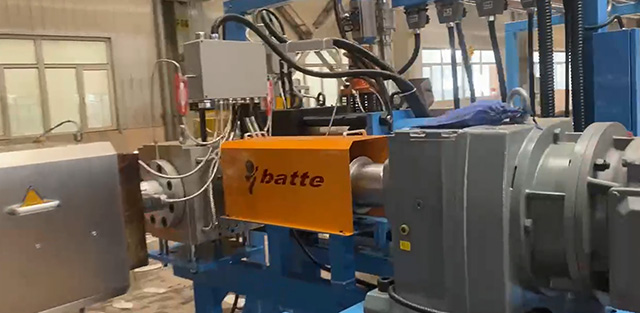

The application of melt pumps in plastic granulation is crucial, it mainly plays the role of stable conveying, pressurization and accurate metering, thus significantly improving the efficiency of the plastic granulation process and product quality. The following are the specific applications of melt pumps in plastic granulation:

Stable conveying: Plastic granules in the molten state, its viscosity, temperature and fluidity will be affected by a variety of factors, such as the fluctuation of the screw extruder, the unevenness of the raw material, etc.. The melt pump can provide a constant back pressure, so that the melt is uniformly sheared and compressed in the pump, thus maintaining a stable conveying state and reducing the fluctuation and pulsation of the melt in the conveying process.

Pressurization: In the plastic pelletizing process, the melt needs to be extruded through a certain pressure. Melt pumps are able to pressurize the melt to the required pressure level, ensuring that the melt passes smoothly through the mold or die to form uniform pellets. This pressurization helps to increase the capacity of the pelletizer and the quality of the product.

Accurate dosing: Melt pumps have an accurate dosing function and are able to deliver the melt at a set ratio and speed. This is particularly important for plastics pelletizing processes that require precise control of raw material ratios and extrusion volumes. By adjusting the speed and flow rate of the melt pump, it is possible to achieve precise control of the amount of melt delivered to meet the production requirements of different products.

Improved product quality: The steady conveying and pressurizing effect of melt pumps helps to reduce the fluctuation and pulsation of the melt during the extrusion process, making the extruded plastic pellets more uniform, smooth and dense. At the same time, the melt pump can also reduce the degradation and decomposition of the melt during the extrusion process, reducing the rate of defective products and improving the overall quality of the product.

Improve production efficiency: the efficient and stable work of the melt pump can reduce the downtime and failure rate in the plastic pelletizing process, and improve the operational stability and reliability of the equipment. This helps to reduce production costs, improve production efficiency and product yield.

Adaptation to a wide range of plastics: Melt pumps are suitable for a wide range of types of plastic melts, such as polyolefins (e.g., PP, PE, POE, etc.), polyesters, polyamides, and so on. By choosing the right pump body and seal material, the compatibility and durability of melt pumps in different plastic pelletizing processes can be ensured.

In summary, the application of melt pumps in plastic granulation is multi-faceted, it can not only improve production efficiency, reduce production costs, but also significantly improve product quality and stability. Therefore, in the plastic granulation industry, the melt pump has become one of the indispensable and important equipment.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755