- Position:

- Batte Melt pump > NEWS >

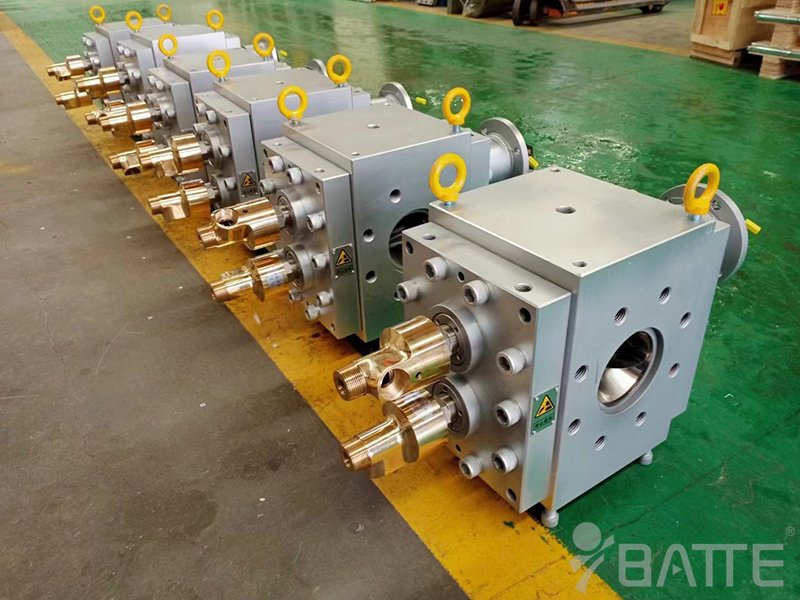

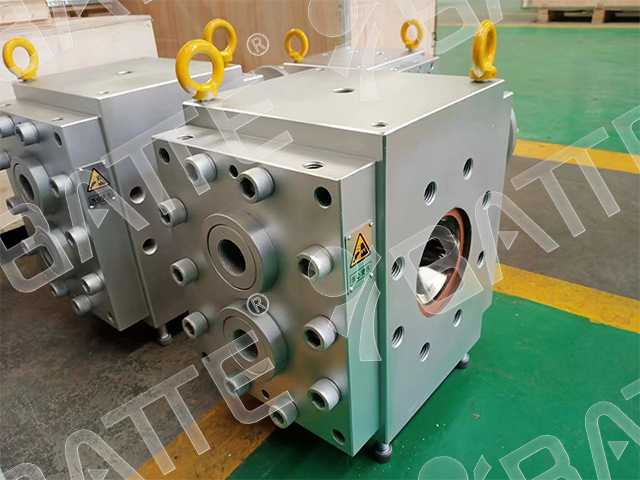

Rubber extrusion melt gear pump

The polymer extrusion melt pump is a specialized melt pump used in the rubber processing industry, primarily for the transportation, pressurization, and metering of high-temperature, high-viscosity rubber melts. Below is a detailed introduction to the rubber melt pump:

I. Definition and Function

The rubber melt pump is a positive displacement conveying device that utilizes the change in working volume caused by the meshing of the driving and driven gears to transport the melt. It is primarily employed in the rubber extrusion molding process, such as the production of rubber tubes, rubber sheets, rubber belts, etc. It ensures stability, uniform pressure, and precise flow control during the melt transportation process.

II. Structure and Working Principle

The rubber melt pump primarily consists of a pump casing, driving gear, driven gear, sliding bearings, front and rear end plates, gland seals, etc. During operation, the tooth profiles of the two gears, the pump body, and the side covers jointly form the feed zone, conveying zone, and discharge zone of the pump. When the gears rotate in the prescribed direction, the rubber melt enters the tooth spaces of the two gears in the feed zone. As the gears rotate, the melt is carried into the conveying zone from both sides. The re-meshing of the gears forces the melt in the tooth spaces to be extruded into the discharge zone and pressurized into the outlet pipeline. This working principle enables the rubber melt pump to stably transport the melt under high pressure.

III. Application Areas

The rubber melt pump is widely used in the rubber processing industry, particularly in the rubber extrusion molding process. It can be paired with rubber extruders to stably transport high-temperature, high-pressure rubber melts to the extruder head, thereby ensuring the dimensional accuracy and surface quality of the extruded products. Additionally, the rubber melt pump can also be utilized in rubber injection molding, rubber calendering, and other processes.

IV. Advantages and Characteristics

Excellent Stability: The rubber melt pump employs a positive displacement conveying principle, ensuring stability during the melt transportation process and reducing fluctuations and pulsations.

High Pressure Capability: The pump outlet can achieve high pressures, meeting the pressure requirements of rubber processing.

Precise Flow Control: By precisely controlling the pump's rotation speed and flow rate, it ensures accurate flow control of the rubber melt during transportation.

Wear Resistance and Durability: Manufactured with wear-resistant materials, the rubber melt pump exhibits high wear resistance and durability, suitable for long-term continuous operation.

Easy Maintenance: The relatively simple structure of the rubber melt pump facilitates disassembly, cleaning, and routine maintenance.

V. Operation and Maintenance

When using the rubber melt pump, attention should be paid to the following points:

Regularly check the pump's transmission system for normal operation, such as wear or looseness of gears and chains.

Regularly inspect the cleanliness and unobstructedness of the pump's inlet and outlet pipelines to prevent clogging that may affect transportation efficiency.

Regularly lubricate the pump's bearings and gears to ensure the smooth operation of transmission components.

Observe the pump's operation; in case of abnormal noises or vibrations, promptly stop the pump for inspection.

Regularly clean and maintain the pump to extend its service life.

In conclusion, the rubber melt pump is a crucial piece of equipment in the rubber processing industry, boasting advantages such as excellent stability, high pressure capability, and precise flow control. Proper maintenance and care during use are essential to ensure its smooth operation and extended service life.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755