- Position:

- Batte Melt pump > NEWS >

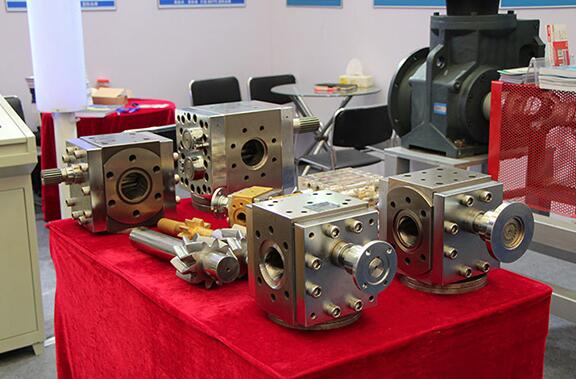

Precautions for selecting cross axis universal joint for melt gear pump

When selecting and configuring the cross-shaft universal coupling for a melt gear pump, which transmits torque between the pump and the motor, it is important to pay attention to the following points given its high angle compensation capability, compact structure, smooth and noiseless operation, strong load-bearing capacity (with torque reaching over 6000KN·M), suitability for high-power transmission, and notable energy-saving effect. This type of coupling is widely used in various applications. For polymer melt conveying gear pumps, the key considerations are:

1.Understanding the Load Characteristics: Clarify the magnitude and type of load transmission, whether it is a unidirectional constant load, pulsating load, or bidirectional alternating load, and the specific working condition factor.

2.Working Environment: Assess the potential impact of harsh environmental conditions such as high temperature, dust, water spray, chemical corrosion, and the need for short maintenance cycles.

3.Site Installation Conditions: Determine if there are any restrictions on the installation location and the specific installation length required.

4.Rotational Speed and Dynamic Balance: Verify the rotational speed of the universal coupling itself and determine whether dynamic balancing is necessary to ensure smooth and stable operation.

Zhengzhou BATTE Melt Pump Co., Ltd. is a professional supplier of melt gear pumps, capable of meeting the conveying, metering, and boosting needs of polymer melts with varying viscosities. It offers a wide range of melt gear pump specifications, from 0.2cc/r to 20000cc/r, tailored to suit diverse industrial requirements.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755