- Position:

- Batte Melt pump > NEWS >

Usage of melt metering pump

The method of using a melt metering pump is as follows:

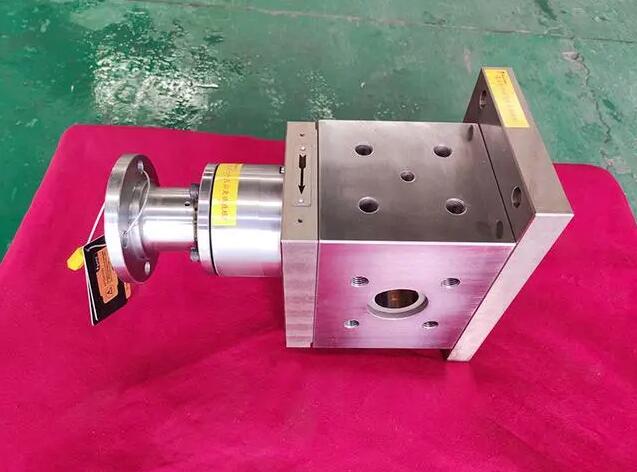

1. Carefully open the packaging of the pump and carefully inspect to ensure that the pump is not damaged or any components are missing. Any impact or fall can cause serious damage, so it is recommended to use appropriate installation methods, such as using lifting rings for installation.

2. Accurately determine the inlet and outlet of the pump during installation, ensuring that the pump shaft rotates clockwise. At the same time, when installing the motor, reducer, universal coupling, and pump, the pump must be fixed on the base to ensure the concentricity between the pump seat and the motor drive shaft. There must be no jamming during rotation to avoid gear jamming or drive shaft fracture.

3. Check all pipelines to ensure they have independent support from the pump and do not apply additional force to the pump. At the same time, check if there is any leakage at the junction of the pipeline and other accessories. Valves and control instruments should also be ensured to function properly.

4. Check the rotation of the pump shaft. Rotate the coupling by hand and check if the pump shaft coupling and motor shaft rotate evenly. If there is any friction or bite, it should not be delivered for use. The cause of the fault should be identified and eliminated.

5. Check the rotation direction of the pump. Inch the motor and check if the rotation direction of the pump shaft is consistent with the direction of the steering sign on the pump.

6. The melt metering pump should be preheated evenly before loading, and the temperature rise should not exceed 120 degrees per hour. Do not start the melt metering pump before it reaches the operating temperature, as cold start is the most likely time to cause pump damage.

7. When starting the melt metering pump to load, it should run at low speed (such as around 5rpm) for a period of time. After each bearing is fully lubricated, it can be loaded and operated, and then slowly increase the working pressure. After the overall operating condition is relatively stable, the pump and the entire system can be gradually adjusted to normal process speed and pressure.

Please note that when using a polymer melt pump, it is essential to follow the manufacturer's instructions and recommendations, and ensure that the operator has the necessary professional knowledge and experience to ensure safe and effective operation. At the same time, regular maintenance and inspection of the pump is also necessary to ensure its long-term stable operation.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755