- Position:

- Batte Melt pump > NEWS >

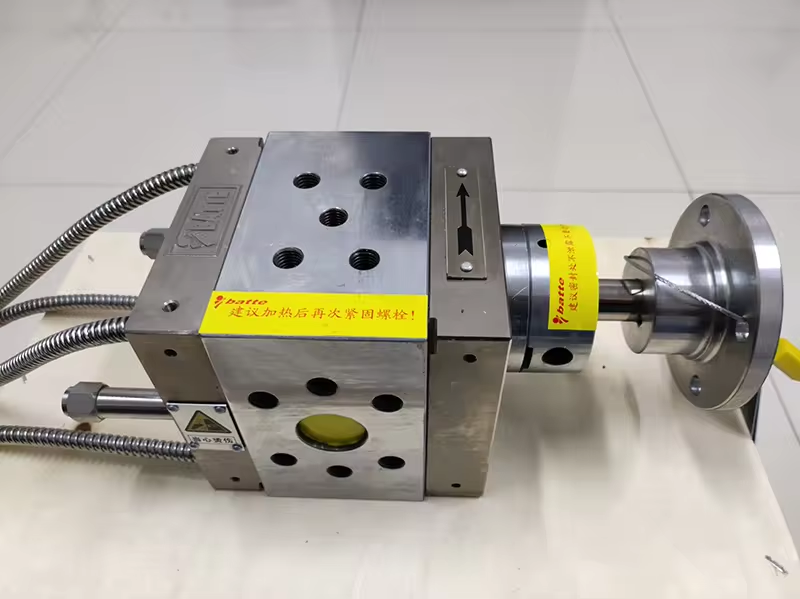

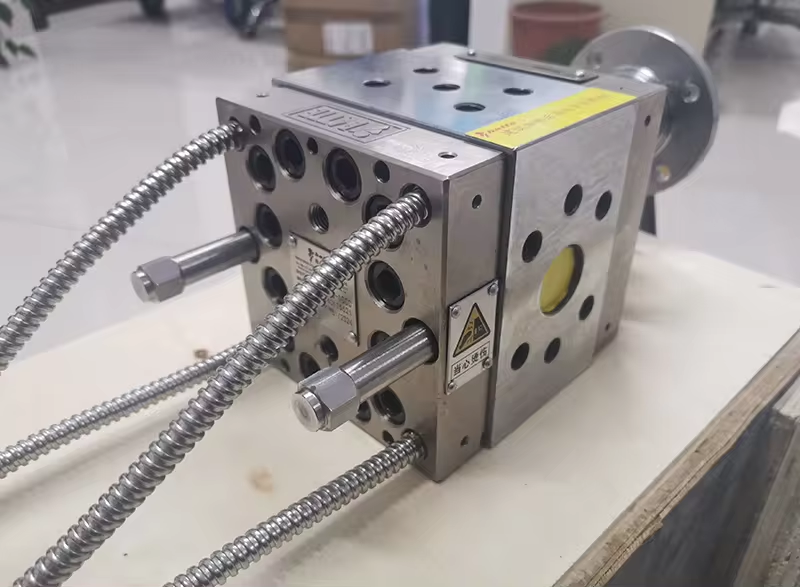

melt pump for PP plastic hollow cross section plate extrusion line

The melt pump of PP plastic hollow cross section plate extrusion line, as a key equipment on the production line, its stable and efficient performance is crucial for the smooth operation of the entire production process. The function of the melt pump is to transport plastic melt into the mold at a constant pressure and flow rate, thereby achieving high-quality production of products.

With the advancement of technology, modern melt pumps have made significant improvements in design, material selection, and manufacturing processes. The high-precision gear design and excellent wear resistance material application enable the melt pump to maintain long-term stability and accuracy when conveying plastic melt. At the same time, advanced temperature control systems and pressure adjustment devices ensure that the melt always maintains a constant temperature and pressure during transportation, effectively avoiding quality problems caused by temperature fluctuations or unstable pressure during transportation.

On the production line, the melt pump closely cooperates with equipment such as extruders and molds to achieve continuous and stable production of products. By precise control of the melt pump, automation and intelligence in the production process can be achieved, greatly improving production efficiency and reducing production costs.

However, there are also some issues that need to be noted during the use of the melt pump. Firstly, it is necessary to regularly maintain and upkeep the melt pump to ensure that it is in good working condition. Secondly, when replacing the melt pump, it is necessary to choose a model and specification that matches the original equipment to ensure the stable operation of the production line. In addition, attention should also be paid to the safety performance of the melt pump to ensure timely shutdown in case of abnormal situations and avoid accidents.

In short, As the core equipment of the PP plastic hollow panel extrusion production line, the melt pump's stable and efficient performance is of great significance for improving product quality and reducing production costs. By continuously optimizing design and strengthening maintenance, the melt pump will provide continuous and stable support for the production of plastic hollow section panels.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755