- Position:

- Batte Melt pump > NEWS >

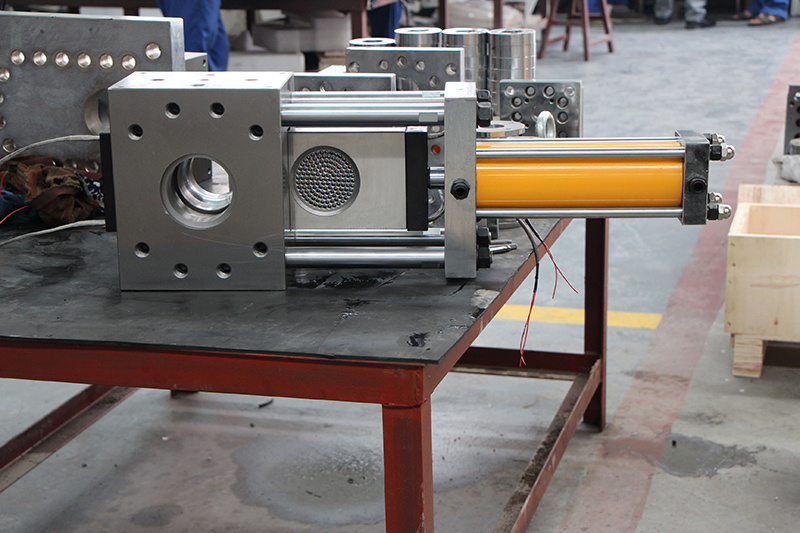

Single plate four mesh circulating four mesh hydraulic screen changer

The four mesh circulating screen changer is suitable for mixed/modified granulation, pipes, sheets, boards, pearl cotton, extruded boards, explosion-proof membranes, hollow boards, wire drawn nets, etc.

The working principle of the four network circulating screen changer

The four mesh circulating screen changer is composed of the main body of the screen changer and four separate filter screen blocks. The four filter screen blocks enter the working state one by one, and filter the polymer medium through the filter screen to clean the medium and produce high-quality products.

When it is necessary to change the mesh, the hydraulic system is used to move the small frame guide bar, so that the working porous plate exits the working position and another porous plate enters the working position. When the small frame guide bar stops moving, open the protective cover, remove the porous plate that needs to be replaced with a new mesh, and then place the porous plate that has been replaced with a new mesh back into the small frame guide bar from the other end. The porous plate moves in one direction, and during the mesh replacement process, attention should be paid to the use of feeding bolts and feeding exhaust holes.

Advantages of Four Network Circular Network Swapper

1. Multi mesh rotating cycle operation, good sealing, wear resistance, and long service life.

2. The overall mesh block is easy to remove and clean, and the filtration is more refined.

3. Material temperature balance transition, especially suitable for high transparency and high-precision products.

4. Do not break the membrane, continuously thread, and replace the filter without stopping the machine.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755