- Position:

- Batte Melt pump > NEWS >

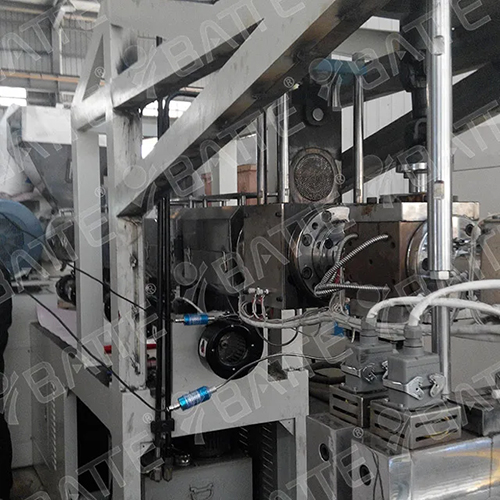

Causes and solutions to hydraulic screen changer failures

In the process of using the hydraulic screen changer, the following common failures may occur. For these failures, we give specific solutions.

1. Material leakage: When using the hydraulic screen changer, material leakage may occur. This may be caused by the hydraulic screen changer's bolts or front and rear flange connection bolts loosening. At this time, we can take the method of tightening the bolts to solve this problem. In addition, if the screen pressure of the hydraulic screen changer is too high, it may also lead to material leakage. We can appropriately reduce the screen pressure to avoid this situation.

2. The slide plate can not be pushed: the slide plate of the hydraulic screen changer can not be pushed may be caused by the debris in the filter tank or the screen exposed slot jammed. In this case, we can pull back to take out the debris, or take other methods to clean the screen. In addition, if the hydraulic screen changer is not lubricated causing the sliding surface to bite, we need to disassemble the machine for repair. At the same time, the hydraulic fit gap is unreasonable can also lead to the slide plate can not be pushed, at this time we need to seek professional help to adjust.

3. oil pump does not oil: hydraulic net changer oil pump does not oil may be due to motor reversal, phase sequence modulation caused by. We can check the connection of the motor and make adjustments. In addition, the oil level is too low or thick oil can also lead to the oil pump does not oil. We need to check the oil level and add hydraulic oil in time. Poor sealing and leakage of the inlet pipe can also lead to the same problem, at this time we need to replace the rubber ring to solve the problem.

4. Noise problem: Hydraulic screen changer may appear noise in the process of use. This may be caused by oil leakage, we need to check and repair the leakage location. In addition, clogged oil filters may also cause noise. We need to clean the filter regularly to keep it clear.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755