- Position:

- Batte Melt pump > NEWS >

What are the reasons for breaking the driven gear of polymer melt pump?

There are 2 main reasons for gear breakage of melt gear pumps for spur gears:

The first reason is that the gear is subjected to a sudden overload will occur when the fracture phenomenon, from the disintegration of the foreign body is not found to enter, and from the fracture site in the root of the gear to see, can be excluded from the possibility of sudden overload fracture of the gear.

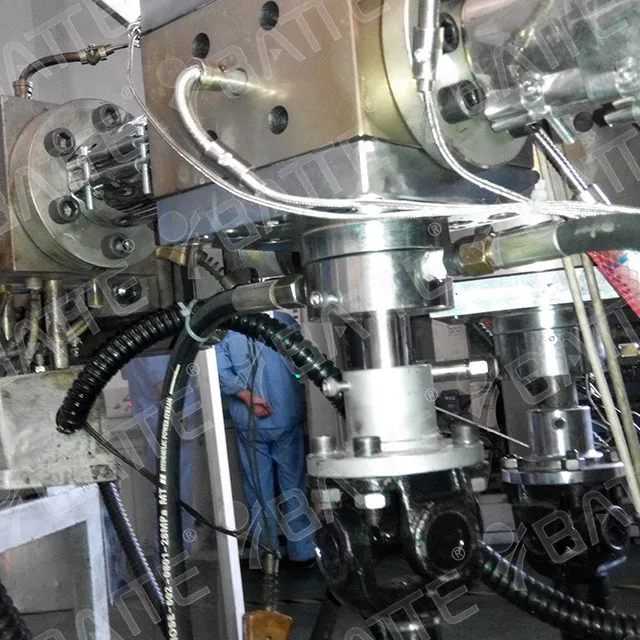

The second reason is because the gear teeth like a cantilever beam, loaded to the root of the bending stress generated at the large, coupled with the root of the transition at the transition part of the size of the larger changes, as well as along the direction of the width of the teeth left behind by the processing of the cutter marks caused by a certain degree of stress concentration, so when the gear is repeatedly loaded, the root of the tooth will produce fatigue cracks and gradually expand, resulting in the breakage of the wheel teeth, which is the melt conveying This is the direct cause of melt pump extrusion driven gear breakage.

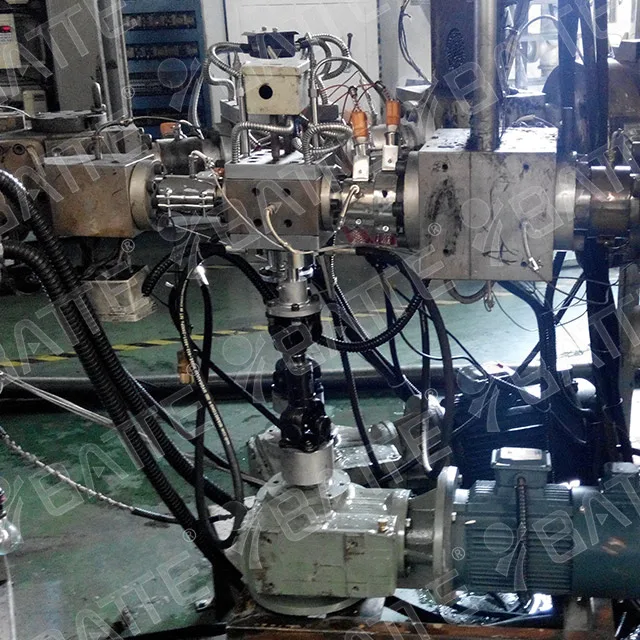

A complete melt pump for extrusion is mainly composed of motor, reducer, universal coupling and pump head. Zhengzhou BATTE provides melt transfer gear pumps with different specifications and models.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755