- Position:

- Batte Melt pump > NEWS >

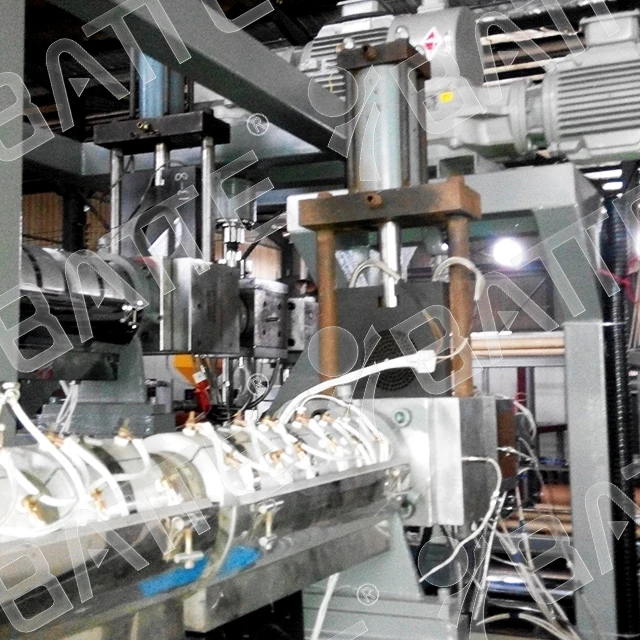

Single Plate fast Hydraulic Screen Changer Application

Single plate screen changer is customarily called single plate fast hydraulic screen changer, this type of screen changer is widely used in the market because of its simple structure, high cost performance, wide range of application, and has the characteristics of no downtime, no leakage of material, smooth flow channel, simple operation and so on. Extruder single plate screen changer has simple structure and easy connection, and can be used with different specifications of single-screw extruder, twin-screw extruder, reactor to do direct connection, simplify the material flow path.

single plate fast hydraulic screen changer

Extruder single plate screen changer for plastic extrusion line application conditions: for sheet, plate, pipe, profile, blown film, cable, pelletizing, rubber and other thermoplastics.

Extruder single plate screen changer structure features: 1, flexible pressure activated seal structure, sealing with the melt pressure automatic activation, automatic compensation; 2, straight-through runner design, more suitable for high-viscosity materials; 3, matched with the accumulator hydraulic station to achieve rapid screen change, no downtime, no leakage, simple and fast operation; 4, can be used with different specifications of the single-screw extruder, twin-screw extruder, the reactor to do the direct connection with the use of the 5, can be customized to take out the net through the changer, and can be used in the same way as a single-screw extruder. It can be customized to take out the extruder screw through the screen changer.

Extruder single plate screen changer extruder technical parameters: 1, temperature resistance up to: 300 ℃; 2, working pressure up to: 50MPa; 3, differential pressure up to: 20MPa; 4, applicable to the melt viscosity: 100 ~ 40,000Pa.s; 5, heating mode: electric heating / thermal media heating.

Single plate fast hydraulic extrusion screen changer optional configuration: 1, highly corrosive conditions - optional high corrosion-resistant material program; 2, mobile installation trolley, integrated storage hydraulic station and electrical control system, easy to maintain the site; 3, integrated melt gear pumps, mixers, drive valve, underwater pelletizing die head and other components of the connection and control, can provide a complete set of programs .

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755