- Position:

- Batte Melt pump > NEWS >

Melt booster pump jamming and end cover leakage

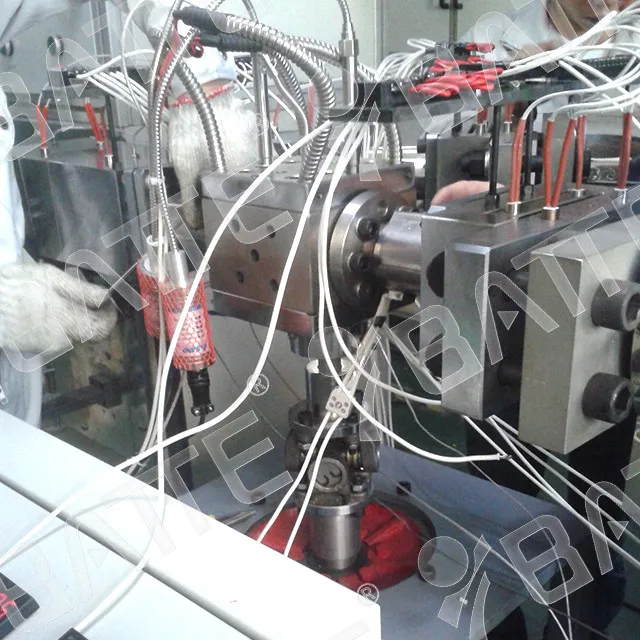

The main reasons for the gear jamming and end cover leakage of the melt booster pump: Zhengzhou BATTE melt pump manufacturer, based on years of experience and analysis, believes that there are several reasons for the jamming and end cover leakage of the melt booster pump:

1. Due to the high assembly accuracy of the melt gear pump, the clearance between the gear shaft and the sliding bearing is 0.2 mm, while the sliding bearing and the gear shaft rely on self-lubrication of the melt material. The lubrication channel width of the sliding bearing is only 24 mm, and the lubrication flow is narrow. Poor lubrication results in increased friction between the gear shaft and the sliding bearing, which is the main cause of jamming.

2. The material of the sliding bearing is hard alloy, which is the same as the material of the gear shaft. Poor lubrication of the flow channel can easily cause the sliding bearing and the gear shaft to jam and lock.

3. Two machining marks can be clearly seen on the sealing surface of the melt booster pump body, proving that the sealing surface of the pump body was not completed in one processing, but was processed multiple times by a lathe, resulting in uneven sealing end faces. The pressure after the melt pump is as high as 25 MPa, and any slight deviation in the machining accuracy of the sealing end face can cause leakage of the end cover.

After analysis by Zhengzhou BATTE melt pump manufacturer, the root cause of frequent stoppage of the extrusion melt pump is that the lubrication channel of the sliding bearing of the melt gear pump is too small to ensure the lubrication amount between the sliding bearing and the main shaft. The sliding bearing and the main shaft are made of the same material as hard alloy, and poor lubrication can easily cause jamming and locking. The fundamental reason for the leakage of melt from the sealing end cover of the melt gear pump is that there is no sealing gasket on the sealing mating surface between the sealing end cover and the pump body. The original manufacturer designed it as a smooth seal, but the machining accuracy of the pump end cover and the pump body cannot be accurately fitted, resulting in gaps and causing the melt to seep over at the end cover.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755