- Position:

- Batte Melt pump > NEWS >

What are the advantages of melt pump control systems for precision extrusion?

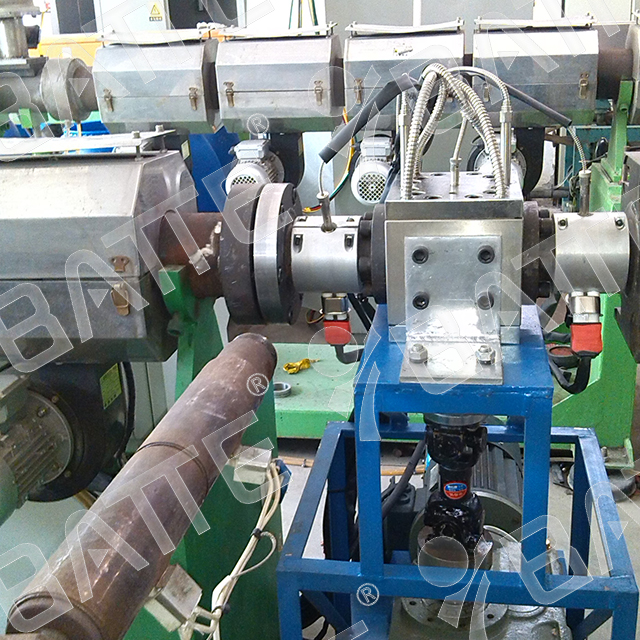

The melt pump control system is an important part of the melt pump extrusion system, capable of controlling the pressure, temperature and flow rate of the melt gear pump in an all-round way. The control of the extrusion pump can be realized manually or automatically through the control system, which can greatly reduce the fluctuation of the extruder outlet pressure caused by various factors, stabilize the pressure of the extrusion die head after the melt pump, and maximize the advantages of the melt pump in precision extrusion.

Increase the control system, there are the following roles and advantages:

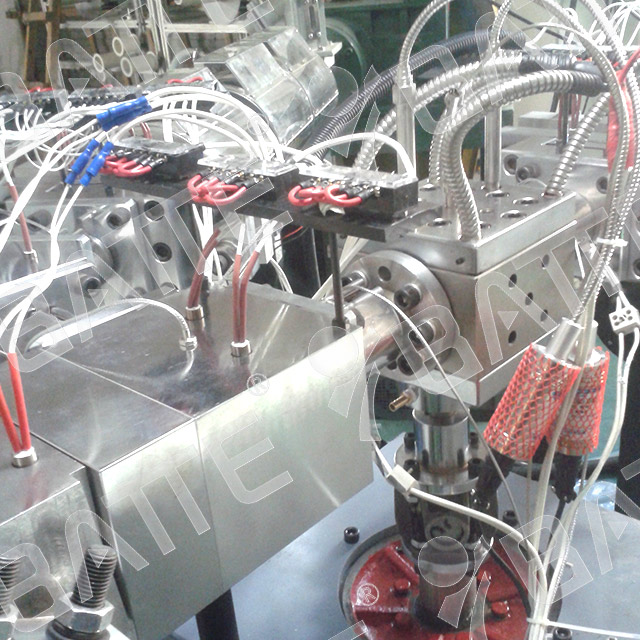

1, improve the polymer melt pump output stability. For example, in the extrusion industry can improve the dimensional accuracy of extruded products, reduce the scrap rate. Melt pump control system in the extrusion process can effectively reduce the pressure fluctuations caused by uneven material dosing, barrel and head temperature fluctuations, screw speed pulsation, etc., to obtain better process results and improve product quality.

2、Reduce energy consumption and ensure the continuity of production. Appropriate control system can obtain higher temperature control performance, better drive power matching, greatly reducing energy consumption, reduce production costs, while significantly reducing the nodes and frequency of manual intervention, improve production efficiency.

3, better speed matching to meet the linear output. Melt pumps have different optimal working conditions according to the different characteristics of the transport medium, viscosity and temperature. The so-called optimal operating point is the melt pump conveying a material in the process requirements of the temperature, viscosity conditions matched with the optimal speed. Finding the optimal working condition point can realize the highest efficiency of melt pump in this kind of medium working condition, which is often very important for users. The control system can record a large amount of historical data, intelligent matching of the optimal operating point, greatly reducing the time of manual commissioning, reducing the cost of manpower and material resources, to provide users with a better experience.

4、Improve the degree of automation, remote control, improve the operator's working environment. Melt pump for plastic extrusion control system is very diverse and can be customized according to the different needs of users. Instrumentation control, PLC control, signal remote transmission, remote monitoring and control and other functions can be easily realized. It is well known that chemical equipment sites often have high temperatures, high noise, and may even have harmful gases. If remote control can be realized, monitoring and operation can be completed in the central control room, which can largely reduce the frequency of employees to the equipment site operation. The control system is very important and indispensable in the automated production process.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755