- Position:

- Batte Melt pump > NEWS >

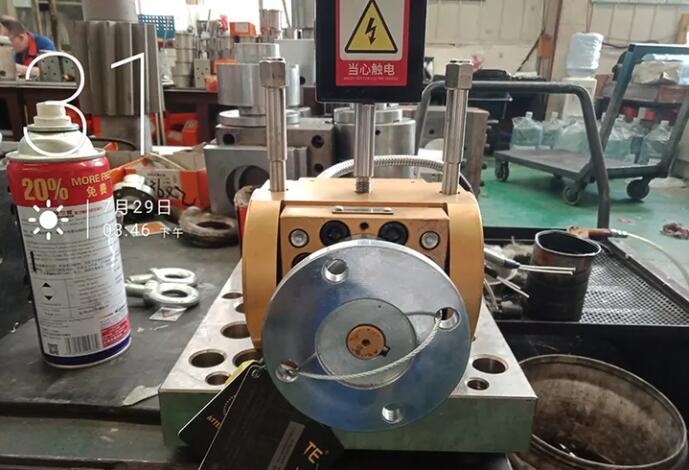

What are the differences between the E-series melt pump and the ZB-B extrusion melt pump?

The company's E-series melt pump is mainly used in conjunction with an extruder to pressurize medium and high viscosity polymer melts, and after pressurization, the flow rate is stable to transport the melt to the die head.

ZB-E high temperature melt pump

The internal structure of the E-series melt pump is basically the same as that of the ZB-B standard extrusion pump. The main difference lies in its appearance: the special cylindrical shape of the E-series melt pump is its advantage. Due to the circular shape of the pump body, it can easily be directly connected to the extruder. The space occupied during installation is smaller than that of standard extrusion melt pumps, making it suitable for extrusion conditions with limited space. The commonly used sealing methods for E series melt pumps are packing sealing, spiral sealing, and two combination sealing methods.

ZB-E series transfer melt pump for extruder

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755