- Position:

- Batte Melt pump > NEWS >

Drip irrigation with melt pump

Introduction to drip irrigation belt melt pump

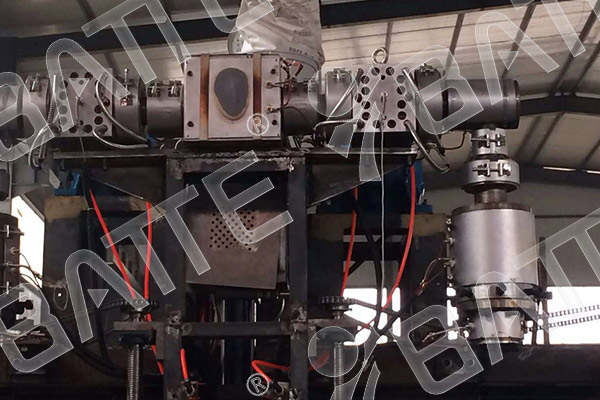

The drip irrigation belt melt metering pump is a positive displacement conveying device, and the flow rate is strictly proportional to the pump speed. Mainly composed of pump casing, driving gear, driven gear, sliding bearings, front and rear end plates, packing seals, etc. The feeding area, conveying area, and discharge area of the pump are composed of the tooth profile of two gears, the pump body, and the side cover plate. During operation, the melt is transported by the change in working volume caused by the mutual meshing of the main and driven gears. The working volume is composed of the pump body, gear teeth, and bearings with side plate function (i.e. the feeding area).

Use of extruder melt metering pump

The melt metering pump of the extruder should be preheated evenly before loading, and the temperature rise should not exceed 120 degrees per hour. Do not start the pump until it reaches operating temperature, as cold start is the most likely time to cause pump damage.

For melt metering pumps that use packing sealing, the position of the sealing gland should be adjusted in a timely manner to ensure the best sealing state. For pumps that use spiral seals, if cooling water is required to assist in sealing, a 1/8 or 1/4NPT connector should be installed on the spiral seal assembly, and then the water source should be connected. For small displacement pumps, do not let the cooling water affect the heating of the pump body.

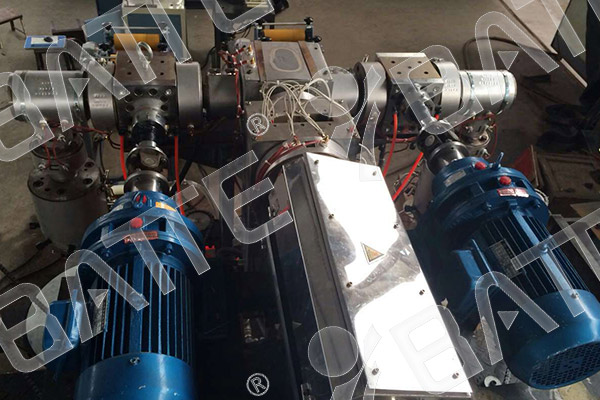

Installation of extruder melt metering pump

The melt metering pump of the extruder should be handled with care during transportation and storage. If the shaft seal is not installed within three months after arrival, it should be cleaned again. When lifting ZB-100CC and above series melt metering pumps, eyebolts should be used.

Before installation, use a measuring tool to check and adjust the concentricity between the pump seat and the motor drive shaft to ensure that the melt metering pump shaft rotates in the direction indicated when ordering during operation, otherwise it may cause input shaft fracture and pump body damage. The base of the melt metering pump installation should be flat and have sufficient strength and rigidity. Under the condition of evenly tightening the bolts, it should be ensured that the input shaft can rotate uniformly without jamming. The installation error of the universal coupling should not exceed its allowable deviation value to avoid causing additional force and shortening the service life of the shaft. Tighten the screws evenly during installation.

The melt metering pump undergoes strict trial operation inspection before delivery, and all indicators and symbols are required. It can be directly put into use after delivery. Regardless of the specification of melt metering pump, when starting and using the loading load, it should be operated at low speed (around 5rpm) for a period of time. After each bearing is fully lubricated, it can be loaded and operated. Slowly increase the working pressure. When the overall operating condition is relatively stable, the pump and the entire system can be gradually adjusted to normal process speed and pressure.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755