- Position:

- Batte Melt pump > NEWS >

Application of Melt Metering Pump in PGA Industry

Green and sustainable development is a global trend. As early as 2020, the goal of achieving carbon neutrality by 2060 was proposed, and in recent years, it has gradually risen from a "plastic restriction order" to a "plastic prohibition order". It can be foreseen that degradable materials have very high application value and development space in the future.

Poly Glycolic acid (PGA) is a new type of green biodegradable material, which can be completely harmless degraded in soil, seawater and other natural environments in half a year to one year. It has been certified as a safe biodegradable plastic material in the United States, the European Union and Japan. At the same time, it also has characteristics such as fast degradation rate, high barrier performance, strong mechanical properties, and good biocompatibility. At present, it is widely used in medical Surgical suture, drug controlled release carrier, fracture fixation materials, agricultural mulch and other fields.

The traditional preparation route of poly (Glycolic acid) (PGA) is mainly as follows: Glycolic acid is directly dehydrated and polycondensated, or Glycolic acid is used to prepare ethylene cross ester, and then ethylene cross ester is ring opened and polymerized. With the great development of coal to ethylene glycol industry in China, the large-scale production of poly (Glycolic acid) (PGA) using dimethyl oxalate (DMO) as the raw material for the preparation of ethylene glycol has become a more feasible process route. The industrialization of this process route will greatly reduce the production cost of poly (Glycolic acid), which has a broad market prospect.

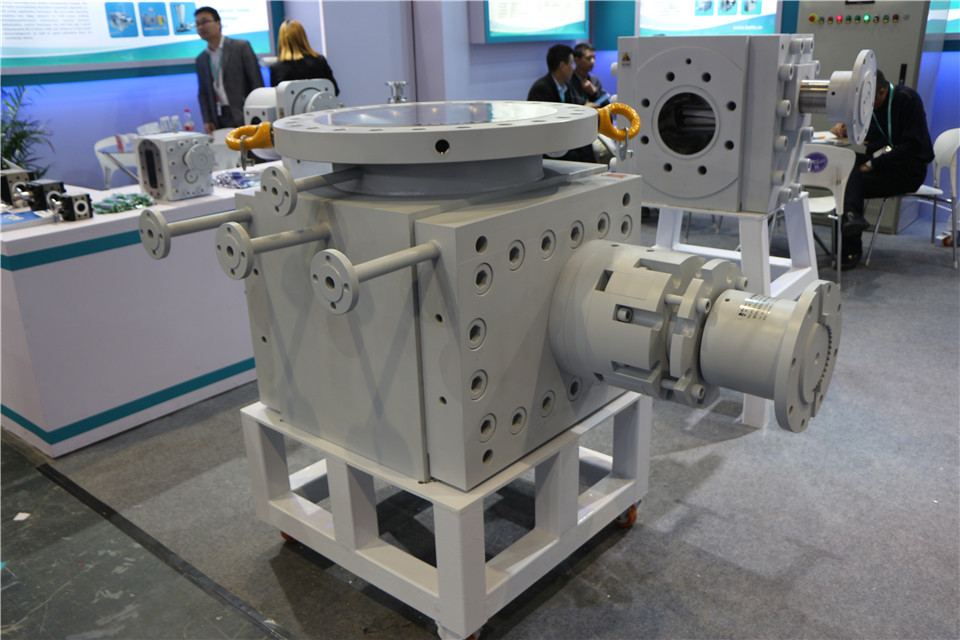

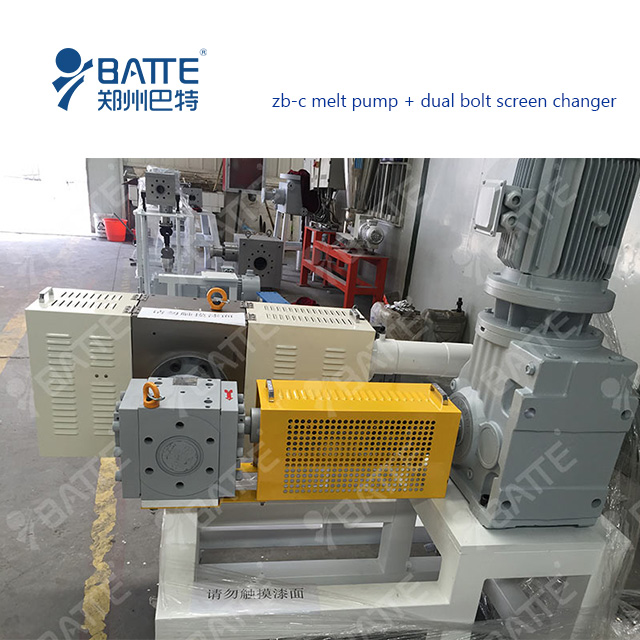

Melt gear pump plays a "heart" role in the production process of poly (Z alkyd) (PGA), mainly used for the transportation of oligomer, catalyst and other melts, as well as the transportation and pressurization of materials in the final granulation process. Poly (Glycolic acid) (PGA )During the production process, oligomers and intermediate products have certain corrosiveness, and the material properties are relatively special, so there are special requirements for the material and structure of gear pumps. In addition, to ensure the stable operation of the system, the gear pump needs to monitor and control temperature, speed, etc. to meet the requirements for flow and control accuracy in the production process.

Email: info@battemachinery.com

Whatsapp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755