- Position:

- Batte Melt pump > PRODUCT > Other Types of Melt Pump >

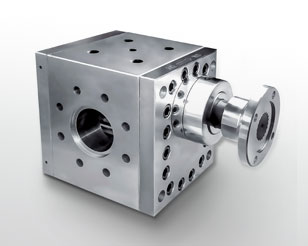

Gear pump is mainly used for transportation, pressurization and metering of high temperature or high viscosity polymer.

1). OEM services provided;

2). Excellent quality assurance;

3). Fast delivery;

4). Worldwide dealer or agent needed.

Batte Melt Pump Zhengzhou Co., Ltd is one of the biggest manufacturer for melt pump, gear pump or metering pump products in China. Being a professional supplier for melt pump products, we have been accumulating adequate experience on the application technique.

Scope of Metering gear pump Field Examples

Polymer Meltfilm, pipe, plate, sheet, granulation

High Temperature or High Viscosity MaterialsPC, PMMA, ABS, HIPS, PET, PVB, PS, PP, PA, PE, PVA

Chemical Fiber Meltpolyester for cotton-fiber, polypropylene

Other Polymer Melt Materialsrubber, asphalt, paint, adhesives, coatings, lubricants

Technical Parameter for Melt Pump Model (ZB-R Series):

Pump Model (0.5-2500CC)

Capacity Delivery 0.1-5400L/H

Recommended Rotation Speed 5-60rpm

Driven Power 0.2-55KW

Heating Power 1-20KW

Working Temperature ≤400°C(750°F)

Working PressureOutput Pressure: ≤40Mpa(6000psi)

Gear FormStraight (Optional)

Voltage380V/50Hz (Optional)

Sealing Methodhelical sealing, packing sealing, or other optional mechanical sealing

Heating Component:Stainless steel heating rod

Tightening Parts: 12.9 high-strength screws

One Whole Set of BATTE Melt Pump System Comprise :

1. Melt Pump

2. Driven Motor System: motor + reducer

3. Control System: PLC touchscreen system

The Performance Advantage of Batte Metering gear pump:

1. Stabilizing outlet pressure;

2. Improving the products quality;

3. Increasing the extrusion output;

4. Reducing unit energy consumption;

5. Prolonging the service time of extruder

The Installation of Our Melt Pump

Installation Method: Motor+Reducer+Universal Coupling+Melt Pump

Installation Method: Motor+reducer+universal coupling+melt pump

You can use control or direct current governor for the motor, and can adjust the flow to your demands optionally. We suggest using servo motor for speed governing if you demand high precision.

Please well check our installation schemes below:

Quality Control System

• Fixed Equipments for Q/C

• Qualified Adequately before Reaching Warehouse

• Randomly Checking Machines before Shipment

-

Place of Origin: Henan, China (Mainland)

-

Brand Name: BATTE

-

Theory: External Meshed Positive Displacement Gear Pump

-

Structure: Gear Pump

-

Usage: Polymer Melt Gear Pump

-

Power: Electric

-

Standard or Nonstandard: Standard

-

Fuel: No Need

-

Pressure: High Pressure

-

Application: ttransportation, pressurization or metering of polymer melt

-

Scope of Application: Almost all kinds of polymers

-

Viscosity:Up to 40000Pas

-

Material for Pump Housing: M4 Steel

-

Gear Tooth:Straight (Optional)

-

Melt Pump Model:0.1CC-6000CC

-

Capacity Delivery:0.05-120000L/H

-

Max. Outlet Pressure: Less than 40MPa

-

Max. Differential Pressure: 275Bar

-

Heating Method:Stainless Steel Heating Rod

-

Sealing Method:Mechanical Sealing (Optional)

| Packaging Details: | Items are packed in wooden cases. |

|---|---|

| Delivery Detail: | 5-6 Weeks |