- Position:

- Batte Melt pump > PRODUCT > Melt Pump for Extruder >

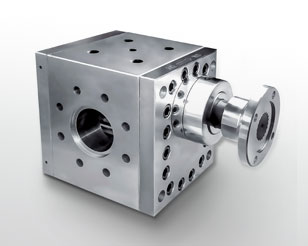

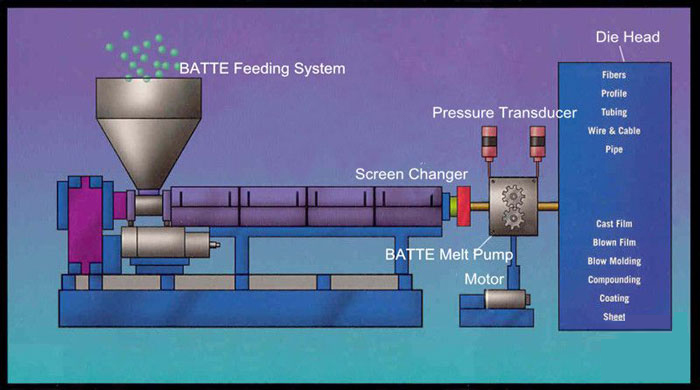

Melt pump for extrusion line is mainly used in conjunction with extruders. It reduces the natural pulsation and irregular conveyance, particularly in single-screw extruders, added to which, the build up of pressure in the gear pump is more efficient in comparison to the extruder. Because of this, less energy or heat is transferred into the polymer and the product is conveyed in a gentler manner. The extruder is indispensable for the manufacture of precision films or micro granulate.

In order to prevent the pump's drive shaft from being driven/pushed out of the housing when there is a high pressure on the suction side (extruder conveying pressure), the drive shaft must be relieved. It protrudes from both sides of the housing and is sealed, so that atmospheric pressure predominates on both sides of the drive shaft. The shaft is thus relieved.

Applications:

Melt pump for extrusion line are widely used in plastics, resins, rubber and chemical products extrusion. Such as: granulation, film, pipe, plate, sheet, synthetic fibers, fiber optics, medical plastic catheters and other industries.

Processable material covering almost the most polymeric materials, such as PE, PC, PP, PVC, HIPS, PS, PA, TPUR, fluoropolymers, polysulfones, polyesters, thermoplastic elastomer, rubber and adhesive fever.

Working Principles of BATTE Rubber Extruder Melt Pump (ZB-R Series):

This type of extrusion melt pump is mainly used in conjunction with extruders or kneaders. It reduces the natural pulsation and irregular conveyance, particularly in single-screw extruders, added to which, the build up of pressure in the gear pump is more efficient in comparison to the extruder. Because of this, less energy or heat is transferred into the polymer and the product is conveyed in a gentler manner. This type of extrusion melt pump is indispensable for the manufacture of precision films or micro granulate.

Place of Origin: Henan, China (Mainland)

Brand Name: BATTE

Usage: Plastic, Rubber Pump and Fiber

Power: Electric or Oil

Fuel: No Need

Pressure: High Pressure

Application: transportation, pressurization or the metering of polymer

Scope of Application: Almost all kinds of polymers

Viscosity: Up to 40000Pas

Gear Tooth: Straight (Optional),Helical gear pump(Optional),Herringbone gear pump(Optional)

Sealing Method: Mechanical Sealing (Optional)

Heating Method: Stainless Steel Heating Rod

|

Packaging Details: |

Items are packed in wooden cases. |

|---|---|

|

Delivery Detail: |

5-6 Weeks |