- Position:

- Batte Melt pump > PRODUCT > Melt Pump for Extruder >

Products Details

Benefits of applying booster pump for polymer:

A. The reduction of stress on the extruder by means of shifting the work pressure to the construction of the melt pump in the molten state;

2. The increase in output per hour;

3. The elimination of variations in production and pressure pulsations, which significantly improves the quality of the product;

4. Saving raw materials through strict manufacturing tolerances;

5. The improvement of the dimensional accuracy in the manufacture of sheets and profiles;

6. Optimization of the surface and optical quality during the production of films, sheets and profiles;

7. The improvement of product quality as regards uniformity and chip size in compounding;

8. Extending the life of the upstream machine;

Specifications

Place of Origin: Henan, China (Mainland)

Brand Name: BATTE

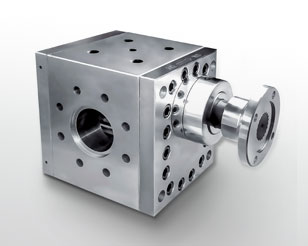

Model Number: ZB-R-250CC

Theory: External Meshed Positive Displacement Gear Pump

Structure: Gear Pump

Usage: Polymer Melt Gear Pump

Power: Electric

Standard or Nonstandard: Standard

Fuel: No Need

Pressure: High Pressure

Application: ttransportation, pressurization or metering of polymer melt

Scope of Application: Almost all kinds of polymers

Viscosity:Up to 40000Pas

Material for Pump Housing: M4 Steel

Gear Tooth:Straight (Optional)

Melt Pump Model:0.1CC-6000CC

Capacity Delivery:0.05-120000L/H

Max. Outlet Pressure: Less than 40MPa

Max. Differential Pressure: 275Bar

Heating Method:Stainless Steel Heating Rod

Sealing Method:Mechanical Sealing (Optional)

Packaging&Delivery

Packaging Details: Items are usually wrapped with foam plastics, and then packed in wooden case.

Delivery Detail: 5-6 weeks after receiving 30% prepayment from the buyer