- Position:

- Batte Melt pump > FAQ >

The use of melt pumps to improve extruder performance

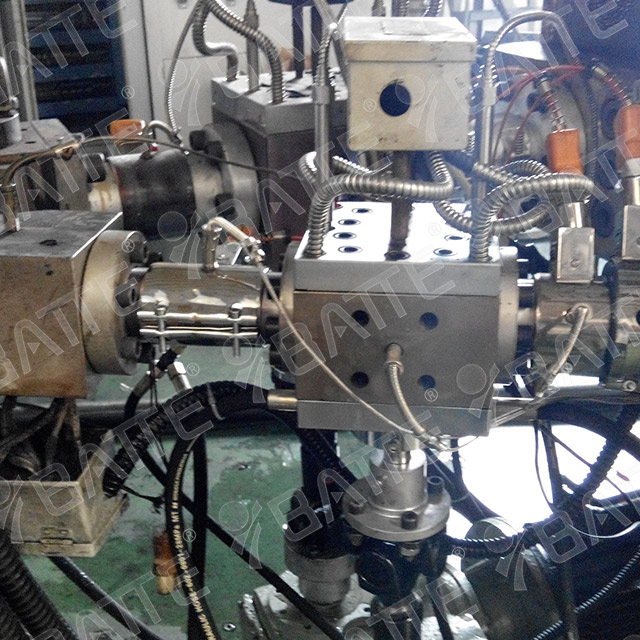

Melt pump is a supporting equipment in the plastic extrusion industry, mainly used in conjunction with extruders to improve their performance. The two main functions of an extruder are heating, melting, and pressure conveying, which are closely integrated. Due to the inherent instability of the melting process, the pressure conveying process also exhibits instability, causing the output of the extruder to be in a state of shock and fluctuation. The main purpose of using a melt pump attached to an extruder is to eliminate these impacts and fluctuations.

1. Pressure conveying mechanism

It is meaningful to compare the pressure conveying mechanism between the extruder and the melt pump. In summary, the melt pump is an active conveying mechanism, thus capable of delivering polymer melt at a highly stable rate. The extruder generates pressure through viscous resistance.

2. Process control

When a melt pump is connected to an extruder, a control system is required to maintain an appropriate balance between the pump speed and screw speed of the melt pump. A simple control measure is to adjust the screw speed so that the inlet pressure of the melt pump remains constant. A more complex measure is to adjust the motor of the extruder and the motor of the pump to achieve a constant extrusion amount, even if the flow resistance increases due to slow and gradual blockage of the filter.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071

Any questions about our products, please feel free to contact us! We promise you high-end products and first-class service.Look forward to our cooperation!!!

- sales@battemachinery.com

- +0086-371-67991755